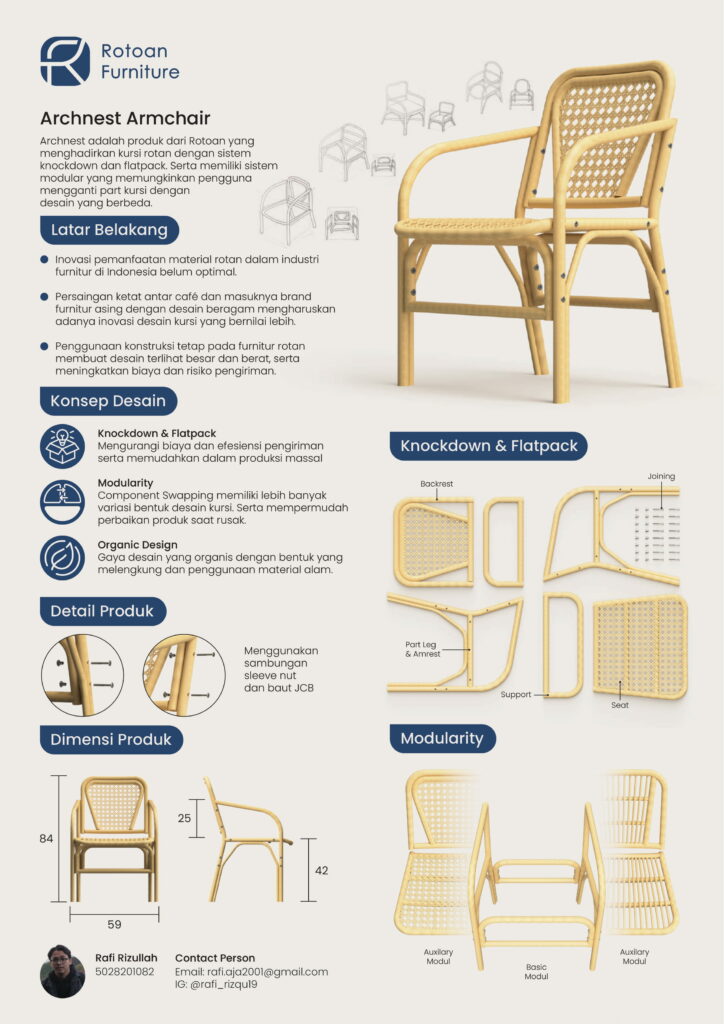

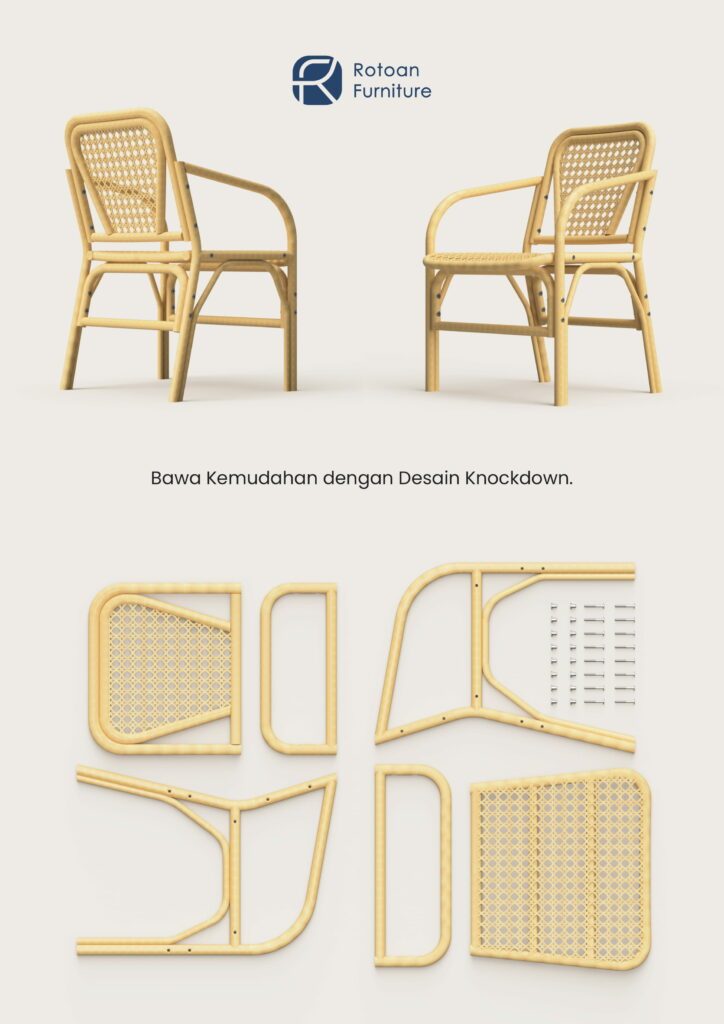

Indonesia is the largest rattan producer in the world, producing around 85% of global rattan raw materials. However, the rattan processing industry sector has experienced a significant decline in production, exports and employment since 2005. One of the main challenges is furniture designs which tend to be conventional and less innovative, because companies more often adapt to buyers’ wishes rather than developing independent designs. In addition, rattan furniture construction methods which generally use fixed construction make it difficult to implement a knock down or flatpack system, which can increase production and shipping costs. In this research, the product designed is a rattan café chair with a knock down system and a minimalist style flatpack. This design is expected to overcome these challenges by introducing an innovative and efficient design in the use of materials and packaging space. Knock down and flatpack systems not only reduce delivery costs but also increase flexibility in café space arrangement. The phenomenon of the development of cafés with attractive interior styles creates opportunities to develop appropriate rattan furniture products. Visitor activities, from office employees to students, are influenced by the comfort and ergonomics of furniture. Choosing the right furniture not only increases the duration of the visit but also attracts the interest of more visitors. Through innovation in design and construction systems, it is hoped that this rattan chair product can meet local market needs and compete in the global market.