Despro ITS Designs Faceshield in Covid-19 Plague Emergency Response

Information

Despro ITS was actively involved in responding to the Covid-19 outbreak. In collaboration with Airlangga University, Industrial Product Design Department designed faceshiled to help medical staff who lack medical instumentation.

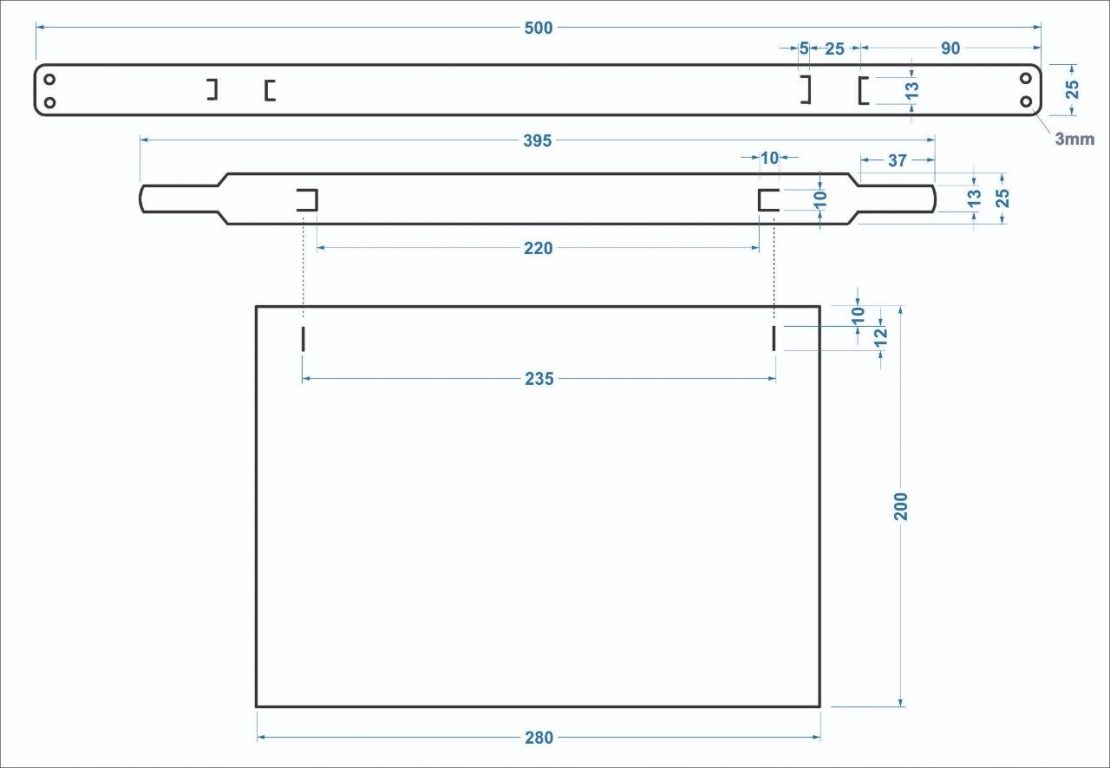

This faceshield design uses two types of plastic for its manufacture. These are High Density Polyethylene (HDPE) and Polyethylene terephthalate (PET) plastic. Such a design and material that is easily obtained, makes this faceshield easy to clean and can be used many times until the plastic becomes dark.

There are 2 types of face shields produced. 3d print method by IDIG Laboratotium and plastic cutting method by the Protomodel Laboratory. Because demand reached thousands in a limited time, the cutting method was developed to mass produce up to 135 thousand items. Using PP plastic (polypropylene) material for the frame and PVC lear for the visor. A simple design is expected to be replicated in various regions. Design patterns have also been disseminated through a timeline network that can be freely copied without any royalties for the design.

The production which has been going on from last Saturday (21/3) was assisted by several student volunteers with a mini-factory system, while prioritizing work safety and safety and social distance

The production target of this Face Shield Mask can meet 500 to 1,000 items every day for meet the demand of 270.000 items across Indonesia. This is due to the rush of orders from hospitals across Indonesia because the use of APD is very much needed while the cases handled at the hospital skyrocketed sharply, coupled with the Covid-19 pandemic.

Latest News

-

Guest Lecture on Interaction Design Course “Designing Effective Interactions on Military Vehicles: An Automotive Designer’s Perspective”

**ITS INDUSTRIAL DESIGN GUEST LECTURE!**

Course: Interaction Design

Theme: “Designing Effective Interactions on Military Vehicles: An Automotive

-

ITS Independent Selection Socialization “Getting to Know More About SMITS FLAT and SMITS ACE”

While waiting for the UTBK results, let’s also find out about other selection paths at ITS that you can

-

“BERHADEP-HADEPAN 3” Event at ITS Industrial Design Department

Hello Designer!! On May 1-3, 2025, the ITS Idustrial Design Department held an event called “BERHADEP-HADEPAN 3”. The event