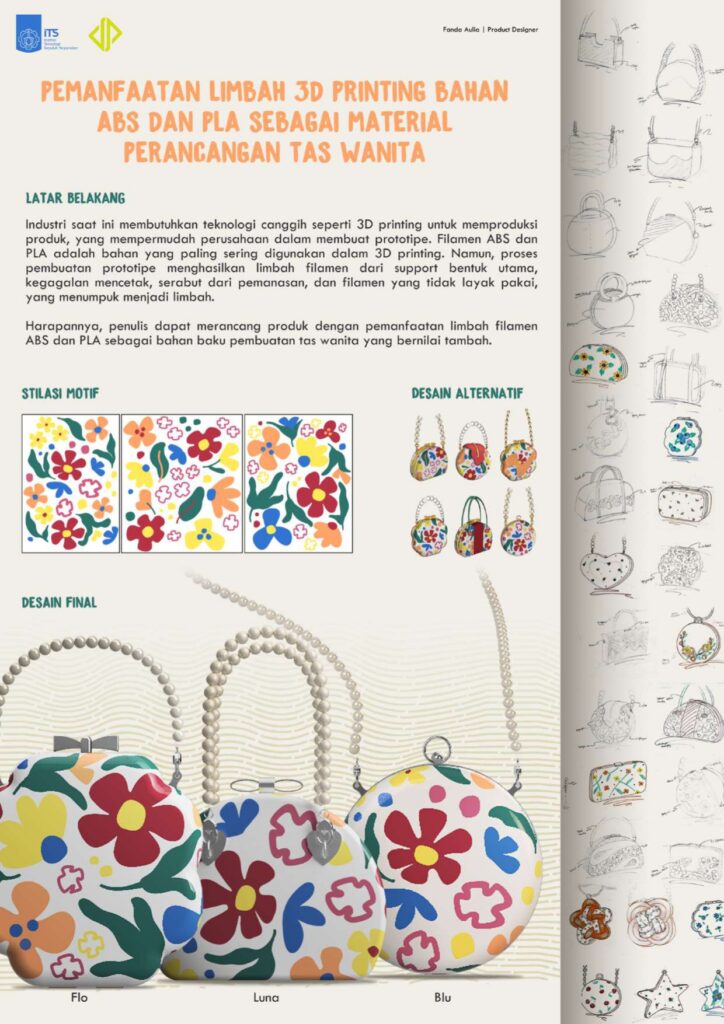

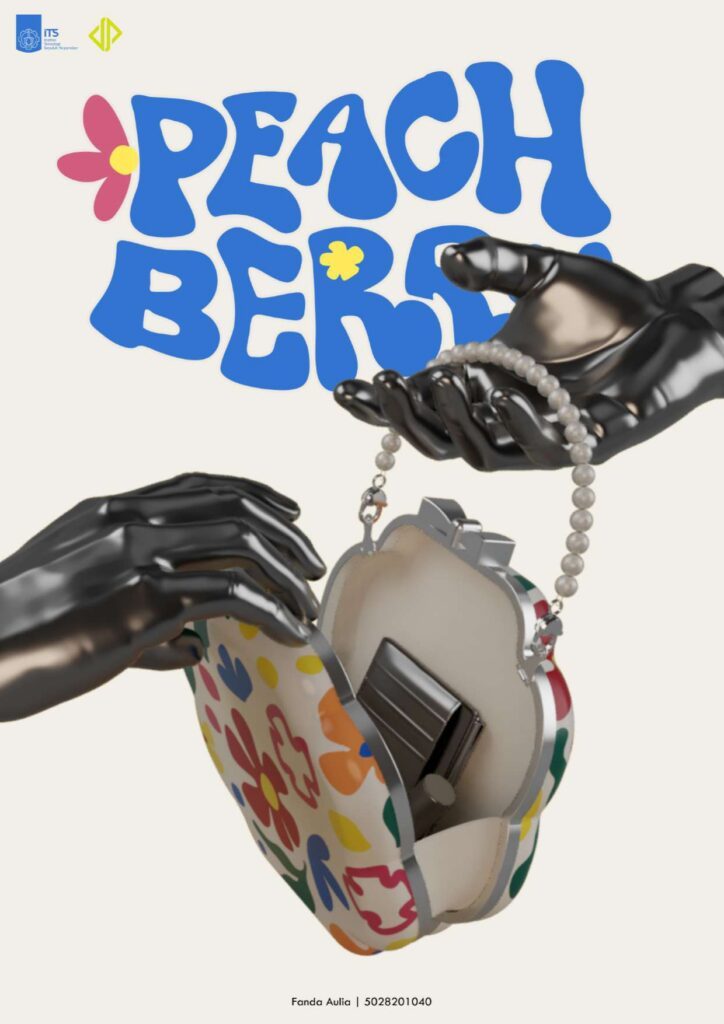

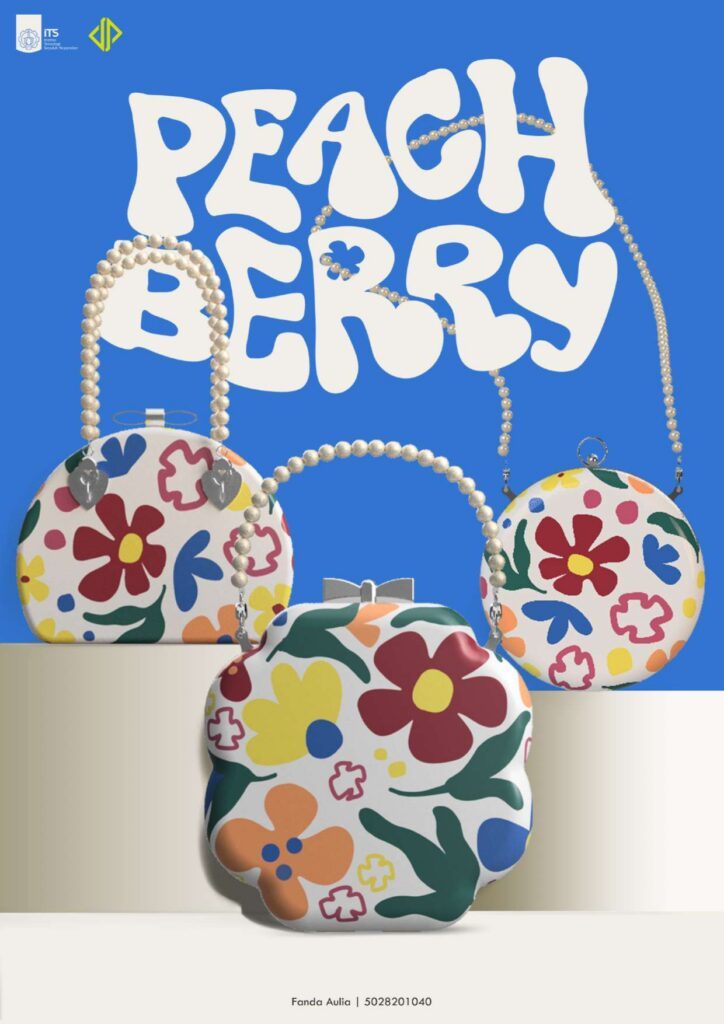

The industry today requires advanced technologies such as 3D printing for product manufacturing, which simplifies the prototyping process for companies. ABS and PLA filaments are commonly used materials in 3D printing. However, the prototyping process generates filament waste from support structures, print failures, stringing from heating, and unusable filament, which accumulate as waste. This study aims to design a women’s hard-shell handbag by exploring the use of melted ABS and PLA filament waste, combined using an electric oven at temperatures around 180-200 degrees Celsius. This process retains the strength and density of the polyblend, resulting in high-quality material. Various bag frame shapes are selected to enhance the structural integrity of the bag, aligning with the design concept and user needs for both aesthetics and functionality. Additionally, the author utilizes the fluid effects in the melted polymer to develop patterns inspired by “Matisse Cut-outs,” adding an aesthetic element to the material.