Rocket Tip Nose Cone Innovation as one of the National Research Priority Program Developments

Uncategorized

Sorry, no posts matched your criteria.

Figure 1. Tip Nose Cone Product

Together with BRIN, ITS researchers developed a Tier 2 Sonde Rocket Tip Nose Cone engineering through the National Research Priority (PRN) program. This research was chaired by Mrs. Widyastuti (Deputy Head of the IoTTP Research Center) together with lecturers from Materials and Metallurgical Engineering to Physics Engineering. In addition, it also involved several students. With a period of less than one year, researchers succeeded in producing several product innovations for rocket nose cone tips. This innovation project is funded by the Ministry of Education, Culture, Research and Higher Education.

The Sonde rocket is a type of sounding rocket that is used to observe atmospheric conditions that cannot be reached by weather balloons and carries a rocket launcher for weather forecasts. This rocket will be launched to an altitude of 200 km, where the tip of the nose cone is the first part to rub against the atmosphere. The temperature due to this friction can reach 1400 degrees Celsius. Therefore we need a material that can withstand high temperatures due to friction.

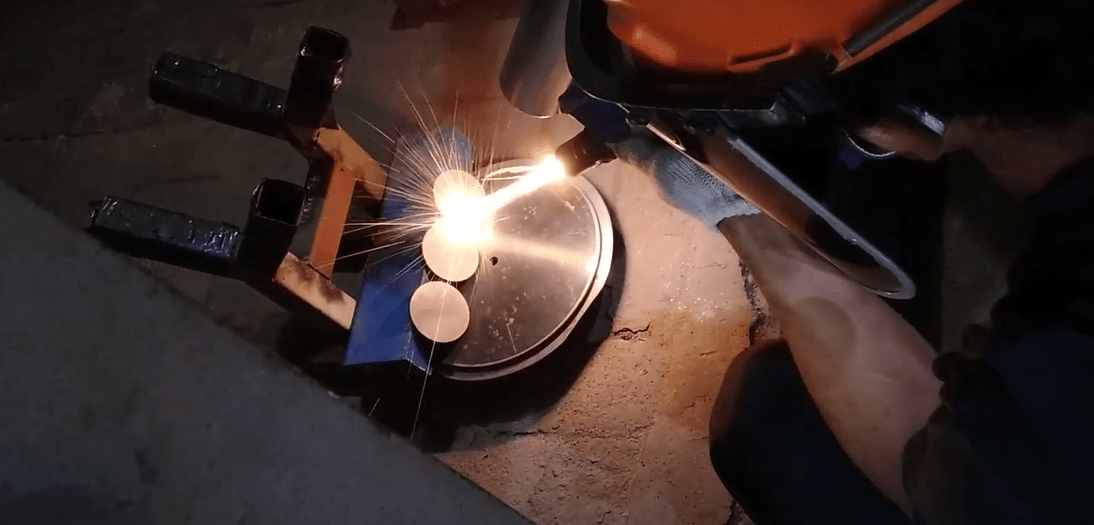

Figure 2. Flame Spray Process for The Tip Nose Cone Specimen

The Sonde rocket uses AISI 4340 specimens, Carbon Fiber Reinforced Polymer, and Hastelloy C276 as tip nose cone substrates. While the coating material used is Durazane for AISI 4340 steel, and YSZ / Al2O3 coating for Hastelloy C276.

The advantages of this rocket nose cone tip include:

• Able to withstand high temperatures, Durazane Coating for AISI 4340 steel is able to withstand up to 400-600 degrees Celsius. YSZ Al2O3 coating for Hastelloy C276 is able to withstand up to 2700 degrees Celsius.

• The coating layer has an adhesive strength of up to 21 MPa on the YSZ coating

• Cheap and light especially on CFRP material compared to other substrates.

Latest News

Sorry, no posts matched your criteria.