Innovate AISITS to Prevent Undersea Oil Pipeline Accidents

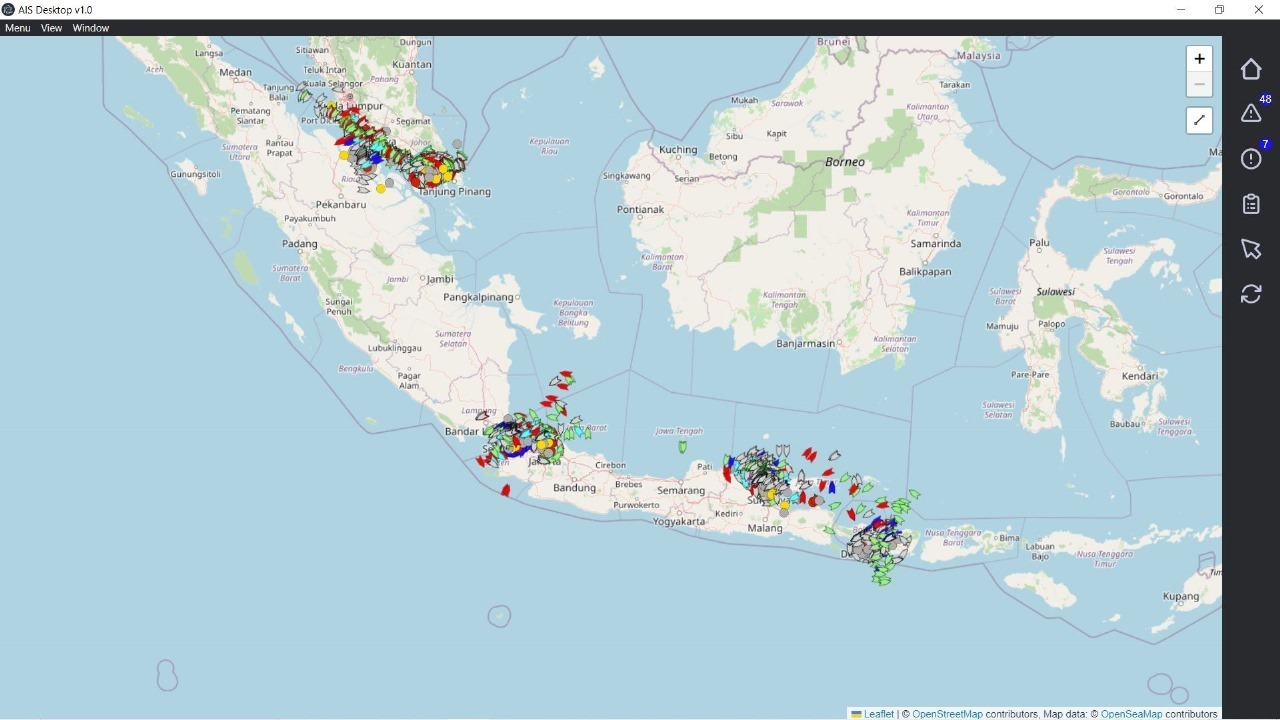

Display of the AISITS software which functions to monitor the location of ships and underwater oil pipelines in Indonesian waters

ITS Campus, ITS News – The Automatic Identification System innovation of Institut Teknologi Sepuluh Nopember (AISITS) has been successfully implemented in several oil and gas companies in Indonesia. The presence of this innovation answers the potential for underwater oil pipeline accidents due to ship anchors that still occur.

One of the AISITS researchers, Dr Eng Dhimas Widhi Handani ST MSc, revealed that AISITS is an innovation developed by the Center for Excellence in Science and Technology for Ship and Marine Installation Safety (PUI Kekal). The implementation of AISITS in oil and gas companies aims to prevent underwater oil pipeline accidents. “This stems from the incident of an underwater oil pipe fire caused by a ship anchor that occurred,” he explained.

AISITS works by providing data on the location of ships and underwater pipes. Dhimas said that through this data, it would be easier for central operators to monitor ships wishing to pass through underwater oil pipelines. “If a ship stops on an oil pipeline, AISITS will immediately provide an early warning,” said Dhimas.

Dr Eng Dhimas Widhi Handani ST MSc when presenting the implementation of AISITS in oil and gas companies at the 2023 IAFMI Innovation Award

Apart from preventing accidents, continued Dhimas, the advantage of implementing AISITS in oil and gas companies is that it can reduce maintenance and upkeep costs. Dhimas said that AISITS is also able to provide the latest conditions of underwater oil pipelines so that oil and gas companies can minimize expenses. “With AISITS, the expenditure required is less than 20 percent,” he said.

Not only does it function as an early warning provider, but according to Dhimas, AISITS is also equipped with several other features. The lecturer at the Department of Shipping Systems Engineering explained that the software is equipped with features for calculating carbon footprints resulting from oil mining activities, forensic analysis when accidents occur, and detecting marine areas that are conservation areas.

AISITS display monitoring the movement of ships and underwater pipes in the Madura Strait

With these various advantages, AISITS can still expand its reach. Currently, the coverage still reaches 100 kilometers, so there are still blind spots in several areas. To overcome this, ships can be given signal boosters in less accessible areas.

There are several assessment criteria in this event, including implementation in the oil and gas industry, novelty of innovation, impact on facility safety and the environment, and effectiveness of innovation. Since 2019, AISITS has been implemented at Pertamina Refinery Unit (RU) V Balikpapan and Pertamina Hulu Energi West Madura Offshore (PHE WMO) at Lamongan Shorebase in 2023.

(from left) AAB Dinariyana Dwi P ST MES Ph.D., Dr. Eng Dhimas Widhi Handani ST MSc, and Gede Bagus Dwi Suasti ST MMT when attending as ITS delegates at the 2023 IAFMI Innovation Award

Apart from Dhimas, there are several researchers from the Reliability, Availability, Management, and Safety (RAMS) laboratory of the ITS Department of Shipping Systems Engineering. These include Prof Dr Ketut Buda Artana ST MSc, Dr I Made Ariana ST MT, AAB Dinariyana Dwi P ST MES PhD, Dr Emmy Pratiwi ST, and Dr Eng Fadilla Indrayuni Prastyasari MSc.

Through implementation in the oil and gas sector, AISITS innovation has succeeded in winning the favorite champion in the 2023 Indonesian Oil and Gas Production Facilities Expert Association (IAFMI) Innovation Award. Dhimas hopes that the presence of AISITS innovation will be able to reduce the risk of ship accidents in oil and gas companies. “The hope is that the sustainability of the supply of oil and gas resources throughout Indonesia will be increasingly maintained,” he concluded hopefully. (ITS Public Relations)

Reporter: Regy Zaid Zakaria

Related News

-

Supports Marine Sustainability, Pertamina Goes to Campus Presents at ITS

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) became one of the partners of Pertamina Goes to

September 05, 2023 15:09 -

Anticipating Lost Pet Dogs, ITS Students Invent a Tracking Bag

ITS Campus, ITS News —Losing a pet is a sad thing for its owners. To anticipate this, a team

September 05, 2023 15:09 -

ITS Students Integrate Smart City Service Features Through Visionaries

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) continues to prove itself as a home for talented

September 05, 2023 15:09 -

ITS Students Innovate Eco-Quake Building Concept

ITS Campus, ITS News — Along with the development of technology, the construction sector has also experienced rapid growth

September 05, 2023 15:09