ITS Students Pioneering Asphalt Modification from Mud and Palm Oil Waste

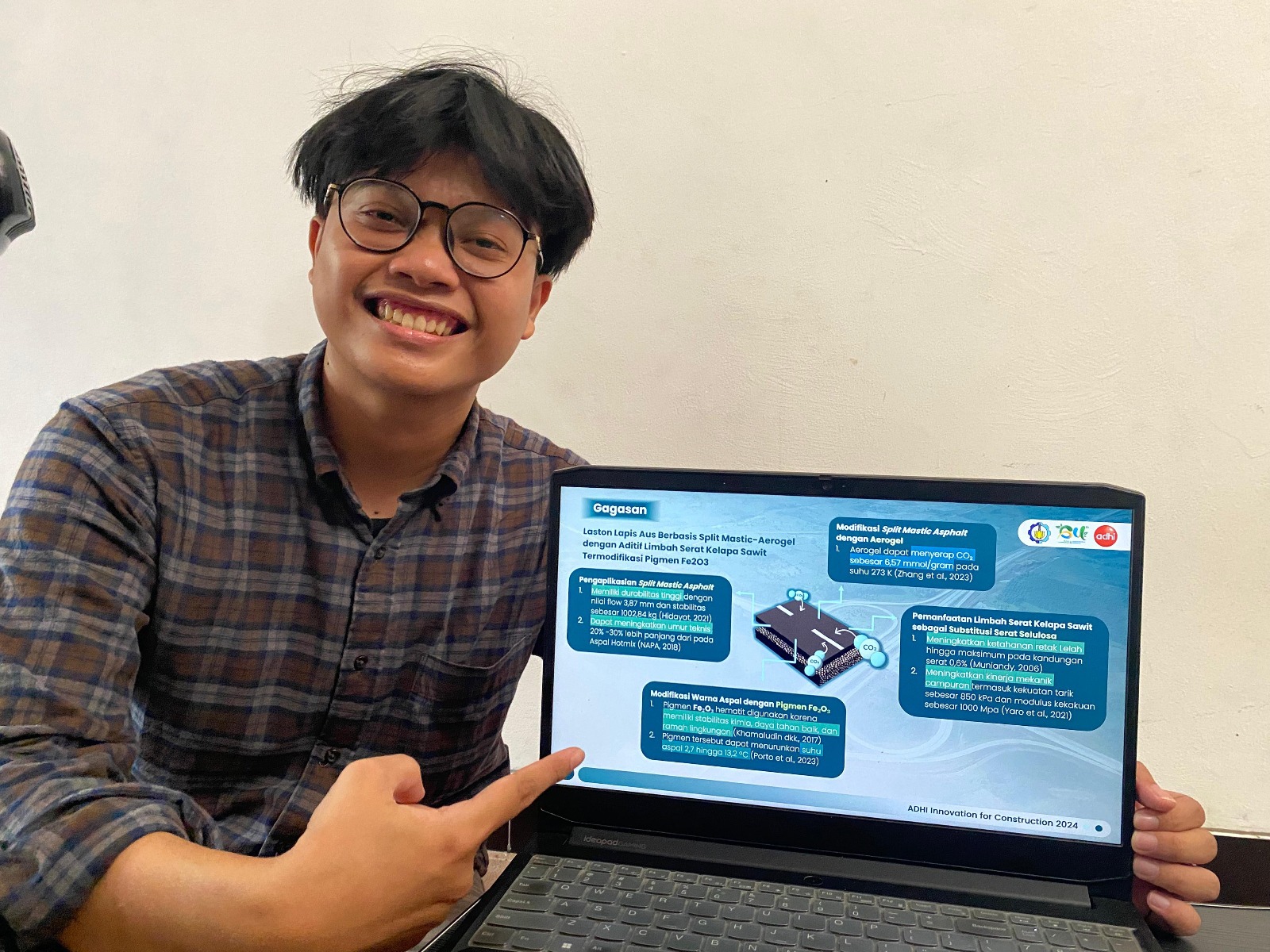

ITS Reswara 64 team leader Bahrul Ilmi Mubarak explains the visualization of modified asphalt innovations from hot mud waste and palm oil fiber

ITS Campus, ITS News — Traffic accidents often occur due to slippery road conditions caused by low asphalt traction. In response to this issue, a team of students from the Department of Civil Engineering at Institut Teknologi Sepuluh Nopember (ITS) initiated the idea of modifying the production of aged asphalt concrete (laston) to enhance the strength and traction of asphalt roads.

Team leader Reswara 64, Bahrul Ilmi Mubarak, revealed that the idea is also based on the composition of asphalt materials, which typically contribute to significant emissions. “So, we innovated the use of waste from palm oil fiber and hot mud from Sidoarjo as additional materials for asphalt layers,” explained the youth from Paser Regency, East Kalimantan.

Bahrul explained that emissions from asphalt roads can result from several actions or events on the asphalt road surface itself. For example, when the asphalt road surface is exposed to sunlight, it can increase carbon dioxide (CO2) gas production by threefold. “Maintenance and paving processes on asphalt roads also contribute significantly to emissions,” said this 2021 batch student.

Reswara 64 ITS team member Em Syahdu Aflais Salam El Wanda when presenting her team’s innovation in front of the ADHI Innovation for Construction 2024 jury

The innovation in asphalt road modification is carried out by adding several materials that can improve road quality and reduce emissions. The first material is aerogel derived from the synthesis of silicon dioxide (SiO2) extracted from Sidoarjo hot mud. Aerogel has the ability to absorb CO2 gas.

The next material is iron(III) oxide (Fe2O3) extracted from hot mud as an asphalt pigment modification. This compound is believed to lower asphalt road temperatures. Finally, the addition of split mastic with palm oil fiber additives to enhance road traction and water absorption capacity. “So, the modification results in the aged layer can also contribute to increasing the technical lifespan of asphalt,” explained Bahrul.

He revealed that his team will collaborate with several parties for the implementation of this innovation. Among them are Lapindo Brantas Inc for the use of hot mud required. Additionally, cooperation with the National Research and Innovation Agency (BRIN) for further research on asphalt modification processes is also underway. There is also cooperation with PT Sinar Mas Agro for the management of palm oil fiber waste.

Reswara 64 Team from ITS after receiving the ADHI Innovation for Construction 2024 award at the head office of PT Adhi Karya (Persero) Tbk, West Jakarta

Under the guidance of lecturer Cahya Buana ST MT, the Reswara 64 team poured their idea into a paper entitled “Innovation of Split Mastic-Aerogel Aged Layer Based on Palm Oil Fiber Waste Modified with Fe2O3 Pigment from Sidoarjo Mud Waste.” Through this innovative idea, the Reswara 64 team successfully clinched the third prize at the ADHI Innovation for Construction 2024 event held by PT Adhi Karya (Persero) Tbk last February.

The team, which also includes Marchel Audy Pratama and Em Syahdu Aflahis Salam El Wanda, hopes that their innovation can be implemented as superior asphalt products for construction companies such as PT Adhi Karya (Persero) Tbk. “Hopefully, this innovation can be further developed with in-depth research and consideration from various functional aspects,” Bahrul concluded. (ITS Public Relations)

Reporter: Ahmad Naufal Ilham

News Translator : Nabila Luthfiani

Related News

-

Anticipating Lost Pet Dogs, ITS Students Invent a Tracking Bag

ITS Campus, ITS News —Losing a pet is a sad thing for its owners. To anticipate this, a team

March 01, 2024 16:03 -

ITS Students Integrate Smart City Service Features Through Visionaries

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) continues to prove itself as a home for talented

March 01, 2024 16:03 -

ITS Students Innovate Eco-Quake Building Concept

ITS Campus, ITS News — Along with the development of technology, the construction sector has also experienced rapid growth

March 01, 2024 16:03 -

Great, ITS Successfully Becomes Overall Champion of the 2024 Indonesian Ship Contest

ITS Campus, ITS News — Proving itself as a home for champions, Institut Teknologi Sepuluh Nopember (ITS) managed to

March 01, 2024 16:03