ITS Students Design Batik Waste Management Equipment for MSMEs

Aditya Mardiansyah when explaining the use of batik waste management equipment made by his team

Kampus ITS, ITS News – In the batik production process, micro, small and medium enterprises (MSMEs) often experience limitations in processing their waste. But waste management is important in this industry because the chemical waste resulting from the coloring process of batik is dangerous for the environment. Determined to help batik craftsmen and craftswomen, students of the Department of Chemical Engineering Institut Teknologi Sepuluh Nopember (ITS) developed a batik waste management technology for MSMEs.

The prototype that was officially launched to the MSME, San Ros Batik, at the end of last month, was an output of their field study on community service conducted by the Department of Chemical Engineering, Faculty of Industrial Technology (FTI) ITS. With the guidance of ITS lecturers, Dr. Eng. Widiyastuti, S.T., M.T., and Dr. Suci Madhania, S.T., M.T., 27 students contributed to making this waste management technology.

The head of the group, Aditya Mardiansyah, explained that in the batik production process, batik craftsmen and craftswomen use textile dyes in the coloring process. The use of synthetic textile dyes and other processes such as the process of removing wax, soaking, and rinsing will produce residual substances such as scattered wax residue or water staining.

Aditya Mardiansyah when demonstrating the use of batik waste management equipment that was made by his team together with the owner of an MSME, Win Ros Batik, Roestianingsih

The remaining substances produce residual waste that is rich in reactive dyes and chemicals that can pollute the environment. So, waste treatment is necessary before the substance is thrown into the environment. “There was a case where a papaya tree, that was accidentally doused with batik wastewater, became bitter in terms of fruit taste, whereas initially, the fruit taste was not like that,” he elaborated.

In response to this negative impact, continued the student who is familiarly called Ardi, he and his team designed a batik waste processing technology that can be easily utilized by batik craftsmen and craftswomen of MSMEs. The design is made using the electron degradation method, namely the treatment of pollutants that can break down complex compounds into simple compounds.

In the case of batik waste, explained Ardi again, this tool breaks down complex compounds in waste into simple compounds namely H2O (water) and CO2 (carbon dioxide) which are safe if discharged directly into the environment. “We use the principle of electrolysis, which needs electrolytes, electrodes, and electricity sources,” Ardi conveyed.

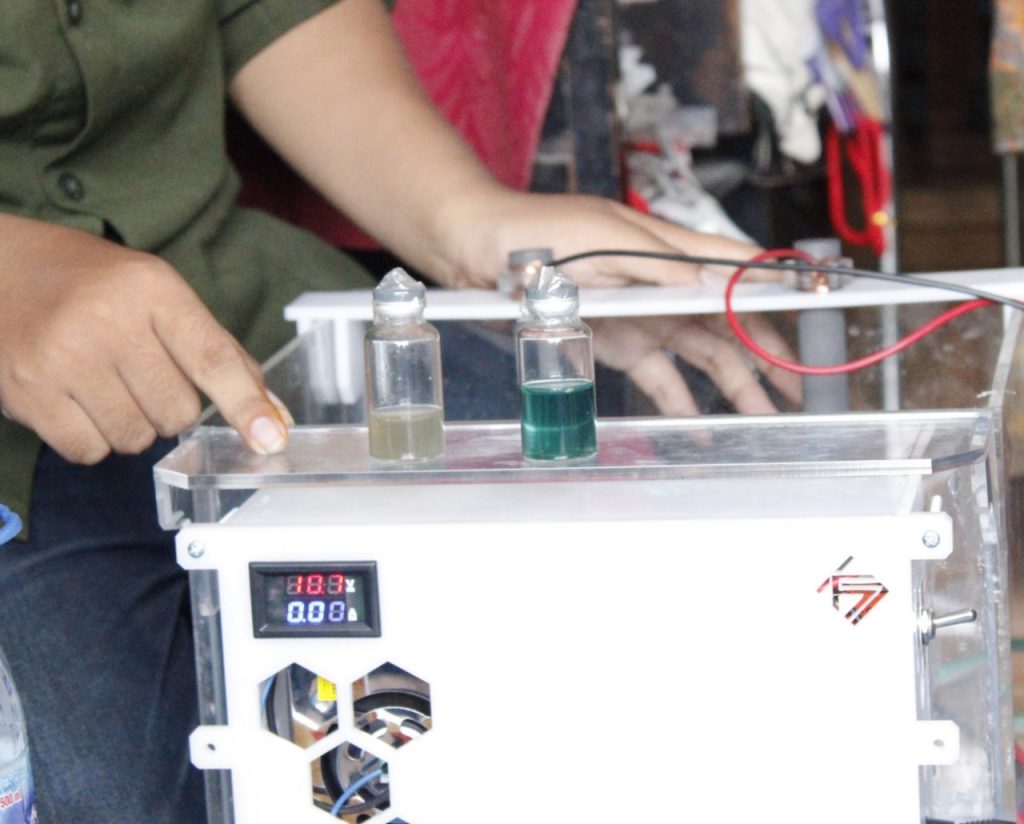

Batik Waste Management Equipment by ITS Chemical Engineering Department students

According to Ardi, the utilization process of this equipment is also easy. Users only need to connect the appliance with electricity then the waste can be directly poured into the acrylic tube. Afterward, the electrodes in the tool will work to degrade waste. The length of treatment varies, depending on the amount of waste poured. “The fastest is 2-3 hours, if there’s a lot, then it can be left overnight,” expressed this young man from Malang.

Ardi explained again that the electrodes used in this case are carbon electrodes because they are considered to have the ability to conduct electricity and can maintain very high levels of heat.

Ardi revealed, the waste that had been processed using his team’s innovation showed a change in color and produced sediment. Wastes that were previously green with a waxy coating inside turn cloudy, which indicates that the waste is no longer dangerous to the environment.

The equipment, which was designed for two months and assembled for four days, is claimed to have many advantages using electrolysis technology, compared to other technologies. This method is considered to be compatible with the environment, energy-efficient, safe, and affordable so that it is considered appropriate for use by MSMEs.

Indicators of treated waste (left) and waste before treatment (right)

The maintenance of this equipment is also relatively easy. Users only need to drain the tank and clean it with equipment that is easily found. The electric power used is also low, only 10 watts. “So it can be likened to a batik craftsman or woman installing an additional lamp in his house,” Ardi added.

Related to the tools that were innovated for this business, Roestianingsih, as one of the UMKM batik craftswomen, claimed to be happy and helped. “Very useful. With this tool, I can dispose of my batik waste without fear of polluting the environment,” stated this woman who started her business in 2012.

This middle-aged woman who lives in Sutorejo, Surabaya, hopes that the equipment created by ITS students can be developed in the future. Given that the batik industry is very difficult to separate from the process that produces waste.

When asked about the future plans for the development of this technology, Ardi said that he and his team wanted to continue to improve the efficiency of it and also add the automation features. “We want to add a feature, i.e. if the tank is full, the tool will automatically run,” he visioned.

He also hopes that the equipment created by his team can help MSMEs in their business processes and can contribute to protecting the environment. “Because this is still a prototype, we hope in the future this batik waste management equipment can be refined again,” he concluded hopefully. (rys/ory/ITS Public Relations)

Related News

-

ITS Wins 2024 Project Implementation Award for Commitment to Gender Implementation

ITS Campus, ITS News —Not only technology-oriented, Institut Teknologi Sepuluh Nopember (ITS) also show its commitment to support gender

January 03, 2020 06:01 -

ITS Professor Researched the Role of Human Integration in Sustainable Architecture

ITS Campus, ITS News –The developing era has an impact on many aspects of life, including in the field

January 03, 2020 06:01 -

ITS Sends Off Group for Joint Homecoming to 64 Destination Areas

ITS Campus, ITS News — Approaching Eid al-Fitr, the Sepuluh Nopember Institute of Technology (ITS) is once again facilitating academics who want

January 03, 2020 06:01 -

ITS Expert: IHSG Decline Has Significant Impact on Indonesian Economy

ITS Campus, ITS News — The decline in the Composite Stock Price Index (IHSG) by five percent on March 18,

January 03, 2020 06:01