ITS Lecturer’s Innovation to Prevent Cracks in Walls with Bacteria

Dr Dra Enny Zulaika M P showing the report of her research

ITS Campus, ITS News – Cracks in the walls are still found in homes in general, the cause estimated due to the production of less robust concrete. It inspired one of the Sepuluh Nopember Institute of Technology (ITS) lecturer to innovate, to make environmentally friendly concrete by adding carbonoclastic bacteria in concrete dough.

Dr Dra Enny Zulaika M P, lecturer of the Department of Biology who made the innovation say, the addition of carbonoclastic bacteria in the concrete dough is assessed to prevent cracks in the wall. It is due to the carbonoclastic bacteria containing calcium carbonate. “Calcium carbonate is what will work to prevent cracks in the wall,” she explained.

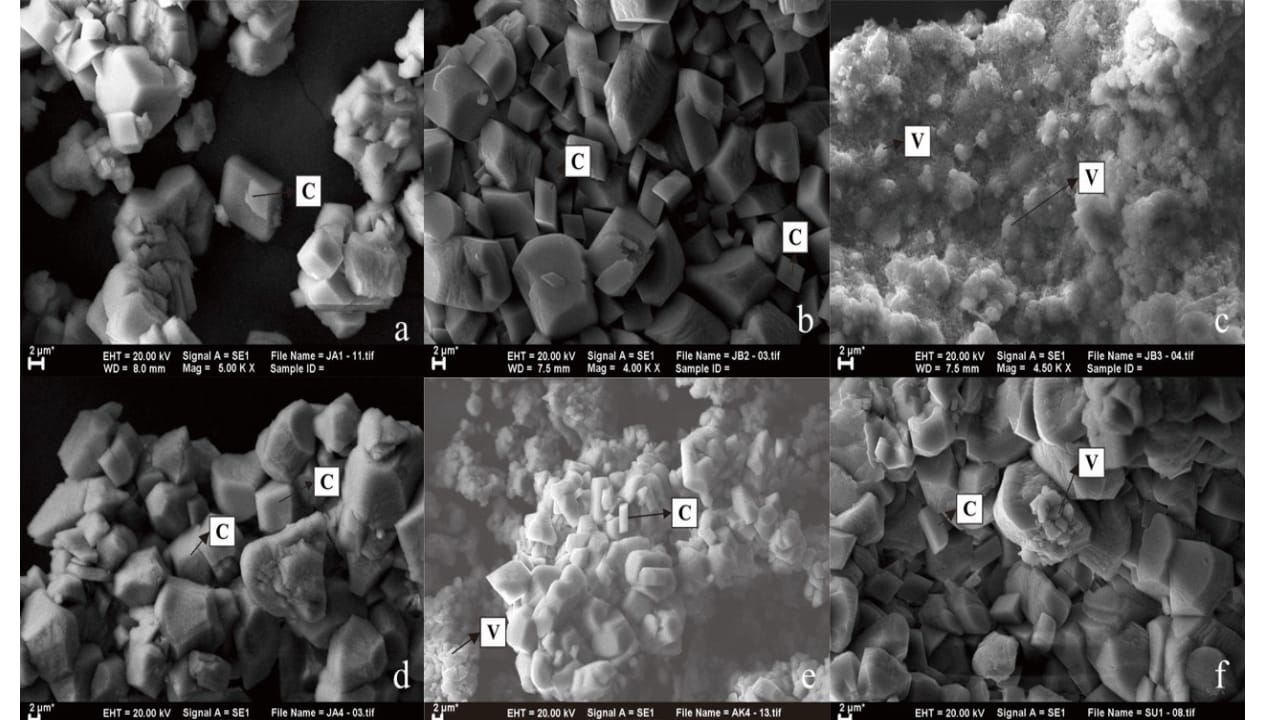

The lecturer, which is often called Enny, explains that carbonoclastic bacteria produce carbonate in the form of crystals. Among them are calcite, vaterit, and aragonite. “The crystals will then sew themselves when there is a cracked wall,” she explained.

Enny opinion, the calcite crystals are the best crystals among the two other crystals. This is because the calcite crystal form is assessed stable. This stability of the calcite crystals makes it excellent for sewing cracks on the walls. “The calcite crystals also serve to strengthen the concrete,” she added.

The graduate lecturer of Gadjah Mada University (UGM) reveals that the carbonoclastic bacteria are taken from the limestone mountainous regions. According to him, lime is the basic ingredient of making cement, so that bacteria originating from the lime region is considered to be adaptable. “I deliberately took from the limestone mountains so that the bacteria easily adapt to other raw materials,” she said.

Images of calcite crystals, vaterit, and aragonite

Enny mentions that there are three limestone mountains in East Java that she chooses. Among them are the Akbar cave in Tuban, Suci Limestone mine in Gresik, and the Jaddih Hill in Bangkalan. “These locations I chose because they need bacteria that come from an extreme environment,” she explained.

Enny reveals concrete with additional carbonoclastic bacteria has advantages over concrete in general. In addition to environmentally friendly, apparently in the manufacturing process also does not require costly costs. “Because we are preventing damage, it needs a cheaper cost than fixing it,” she said.

In his research, Enny cooperates with several lecturers from ITS Department of Civil Engineering. Enny hopes that after the research is completed, concrete with this bacterial content can help the techniques to cope and prevent problems cracking on the wall. “I hope this research is complete and can be implemented so that it can be felt benefits, ” (Dil/Anjani/ITS Public Relation Officer)

Related News

-

Champion of KRAI 2025, ITS Robot Team Officially Represents Indonesia in Mongolia

Bandung, ITS News – The RIVERA Team from Institut Teknologi Sepuluh Nopember (ITS) successfully clinched the first-place title in the

January 27, 2020 21:01 -

Full Appreciation, ITS Recruits Semarang Jago Hacking Golden Ticket Winner

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) never stops providing support for every potential and achievement

January 27, 2020 21:01 -

ITS Doctor Proposes Visual Identity Management Assessment Instrument

ITS Campus, ITS News – Visual identity plays an important role in supporting the reputation of higher education institutions

January 27, 2020 21:01 -

ITS Doctor Innovates Financial Education Game as a Learning Tool

ITS Campus, ITS News – Introducing financial literacy in a fun way is no longer just a discourse. To

January 27, 2020 21:01