Helps Village Potential, ITS Invents Corn Cobs Chopping Machine

Handover of the corncob chopper machine from Abmas team and KKN ITS to the Head of Bolo Village, Gresik on September 3, 2020

ITS Campus, ITS News – The abundance of corn harvested in Bolo Village, Gresik, which is the main commodity in the village, has left corn cobs as waste that has not been utilized by the villagers. Seeing this, the community service Team (Abmas) and Community Service Program (KKN) Institut Teknologi Sepuluh Nopember (ITS) creates a thrasher to utilize corn cob waste into animal feed and raw material briquettes.

The corncob is the part where the kernels attach. This part is often considered to be of no use that most corn farmers throw it away. This is also the case in Bolo Village, Ujung Pangkah District, Gresik Regency, which is known as the first winner of corn production in the northern region for the last 15 years. Corn products from Bolo Village are sold in the form of corn kernels to various cities, leaving only the weevil part of it.

The state of corncob waste in Bolo Village, Gresik, which is still not being utilized properly

According to the team leader, Dr. Wiwiek Hendrowati ST MT, every harvest season in Bolo Village, most of the corn cobs produced just thrown away on a piece of land. Only a few of the corn cobs are used for fish smoking activities there. But the remainder which is still very much is just thrown away until it becomes moldy. “Even though (corn cobs) can still be used and has economic value,” said the lecturer at the Department of Mechanical Engineering ITS.

Wiwiek said that the corncob could be used as animal feed material, first in Bolo Village there was also a farm. Besides, according to him, corn cobs can also be used as briquettes for fuel. Both alternatives to using corn require a chopper to help grind the corn into pieces. Therefore, Abmas team and KKN ITS created a corncob chopper as a form of a contribution to society.

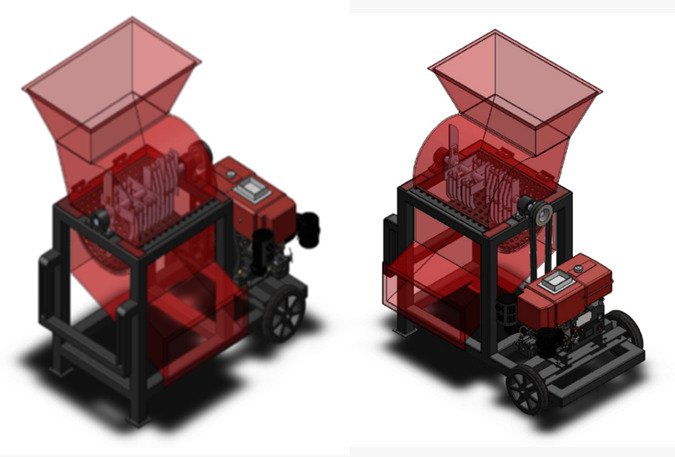

The design of the corn cob chopper machine by Abmas team and KKN ITS

In implementing this program, ITS Abmas team was assisted by two ITS alumni who are now lecturers at Qomaruddin University, Gresik. Besides, this activity involves ten ITS students who live in Gresik, as ITS KKN students. The chopper designed by Wiwiek and the team has three levels of roughness, namely coarse, medium and fine. The degree of roughness depends on what product is being produced.

For example, chopping for animal feed ingredients requires moderate to fine coarseness to be consumed by livestock. This chopping machine also has additional use, which is to use it to smooth twigs and grass. Soft twigs and grass are also usually used by residents of Bolo Village as animal feed. “So that chopping machine can also be used to chop both with a certain level of roughness,” explained the Head of the Automotive System and Vibration Engineering Laboratory.

Demonstration of the corncob chopper machine by the Abmas team and KKN ITS

This corncob chopper machine has been completed and has been tested in Bolo Village. Based on the trials, this machine can smooth eight sacks of corn cobs per hour, equivalent to 120 kilograms. This machine has also been handed over to the Bolo Village through the Village Head on September 3, 2020, and was welcomed by all related parties in the village.

Wiwiek hopes that this activity can be continued at next year’s Abmas team and KKN to continue the potential development of briquette making. “Since this period we have finished the chopper machine, we hope that the briquette manufacturing and marketing scheme can be developed in the next period so that it can grow the economy of the residents of Bolo Village,” he concluded. (ram/ITS Public Relations)

Dr. Wiwiek Hendrowati ST MT (center) along with 10 ITS students who are participating in KKN in Bolo Village, Gresik

Related News

-

Facilitating Creativity of Students, ITS Information Systems Department Presents CCWS

ITS Department of Information Systems students conduct a discussion in one of the available spaces in the ITS Digital

October 30, 2020 15:10 -

ITS Explores Electrification Cooperation with PT Vale Indonesia

ITS Campus, ITS News — Following up on the Memorandum of Understanding (MoU) with PT Vale Indonesia, Institut Teknologi

October 30, 2020 15:10 -

ITS Reaches Top 7 BRIN Collaborators with 309 Scientific Publications

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) continues demonstrating its commitment to strengthening collaboration in research

October 30, 2020 15:10 -

The Only One from Indonesia, ITS Student Becomes Erasmus+ Scholarship Awardee

ITS Campus, ITS News — Civitas academica of Institut Teknologi Sepuluh Nopember (ITS) has once again contributed to making

October 30, 2020 15:10