ITS Students Innovation in Making Environmentally Friendly Potato-Based Plastic

An illustration of easily degraded potato-based plastic products by Hamdan Kafi Magfuri, an ITS student

ITS Campus, ITS News – The Covid-19 pandemic, which changed people’s lifestyles, also led to an increase in the consumption of many products using synthetic plastics. Institut Teknologi Sepuluh Nopember (ITS) student initiated a potato-based plastic. The plastic can be used as animal feed, fertilizer, and easily decomposed by soil.

Hamdan Kafi Magfuri, the Department of Material and Metallurgical Engineering student, initiated this idea. Based on his observations, many people choose to cook food in their own homes compared to the before pandemic era. One of the consequences is the accumulation of single-use plastic bag waste. “Over time, the accumulation of plastic bags will harm the environment,” said the young man who is often called Hamdan.

Therefore, continued Hamdan, this problem requires innovation to reduce or even eliminate the harmful effects it causes. Because the plastic material is tough to decompose by soil, the carbon chain’s length in the material makes microorganisms break down a single new plastics in hundreds to thousands of years. “Thus, the main idea of easy decomposed plastic has other benefits besides turning into the garbage,” continued the student from Lumajang.

With research from previous studies, Hamdan also initiated a plastic based on starch, usually found in tubers. From the many types of tubers, Hamdan chooses potatoes as the main ingredient. The reason is that the availability of potatoes in Indonesia is very abundant. Based on data from the Central Bureau of Statistics (Badan Pusat Statistik or BPS), potatoes are among the major commodities in Indonesia.

Besides, from this election, Hamdan also hopes that the income of potato farmers can increase again. This is because now, the potato farmers’ income in Indonesia is relatively low. Due to differences in the value of various prices, farmers’ selling price and price are sold. “In this idea, we planned that the potato farmers themselves would produce this plastic,” said the student born in 2000.

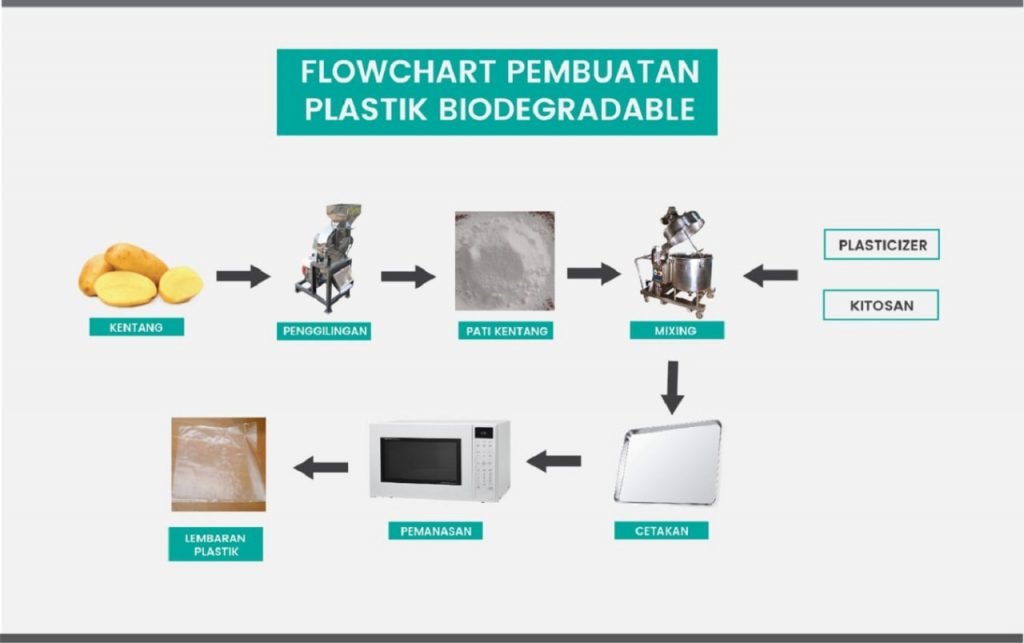

The flowchart of making biodegradable potato-based plastic by Hamdan Kafi Magfuri, an ITS student

According to Hamdan, the making process is relatively easy. The potatoes that do not pass the sale in the market are ground and squeezed to get the starch essence. The starch is then deposited for several days to produce powdery sediment and mixed with a plasticizer and chitosan. This mixture is then deposited, printed on sheet molds, and heated at 120 degrees Celsius for 30-90 minutes.

The plasticizer itself is obtained from glycerol and acetic acid, which function to get plastic properties to compact the dough. “While chitosan can be found from shrimp shell flour and crab shells, it functions to increase the mechanical properties of the plastic, so it has the power to withstand loads,” he explained.

The potato-based plastic, according to Hamdan, has good characteristics. In terms of tensile strength alone, this plastic has 28 MPa, above the SNI standard of 27 MPa. Meanwhile, in terms of water resistance, this plastic has the same capabilities as plastic in general. “This plastic does not emit carbon like plastic in general, so it is safe for food,” he said.

As originally intended, this plastic waste can decompose within 28 days in the soil. Therefore, it must be placed in a place that does not have too much air contact for animal feed and compost. “Hopefully, the benefits of this environmentally friendly plastic can be felt by many parties,” he stated. (mad/sel/ITS Public Relations)

Related News

-

ITS Reaches Top 7 BRIN Collaborators with 309 Scientific Publications

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) continues demonstrating its commitment to strengthening collaboration in research

December 31, 2020 17:12 -

The Only One from Indonesia, ITS Student Becomes Erasmus+ Scholarship Awardee

ITS Campus, ITS News — Civitas academica of Institut Teknologi Sepuluh Nopember (ITS) has once again contributed to making

December 31, 2020 17:12 -

Hydrogen Motor Innovation Leads ITS Antasena Team to Win PLN ICE 2024

ITS Campus, ITS News — After going through a rigorous funding phase, the Antasena Team from Institut Teknologi Sepuluh

December 31, 2020 17:12 -

ITS Researchers Respond to Landslides and Disasters in Sukabumi

ITS Campus, ITS News — The extreme weather that has hit recently has caused various disasters in several regions

December 31, 2020 17:12