ITS Students Created Eco-Friendly Latex Gloves

(from left) Ahmad Fahmi Prakoso, Dewi Setiyaningsih, and Bethari Auchenfloretta showing their poster

ITS Campus, ITS News – The increasing need for medical devices in this pandemic era has an impact on increasing the amount of medical waste, one of which is latex gloves. Seeing the problem, five students of Institut Teknologi Sepuluh Nopember (ITS) initiated environmentally friendly latex gloves with natural materials to overcome the impact of medical waste.

The five were Ahmad Fahmi Prakoso, Wildan Muhammad Mursyid, Dewi Setiyaningsih, Edo Danilyan, and Bethari Auchenfloretta. With the guidance of Material and Metallurgical Engineering lecturer Azzah Dyah Pratama ST MT MEng Ph.D., they created latex gloves by utilizing cheap and abundant natural materials.

Fahmi, a nickname from Ahmad Fahmi Prakoso, explained that the idea of latex glove innovation began in the increasing use of such gloves for medical needs. The use of latex which is generally made from plastic can pollute the soil environment and seawater. “Especially if the management carried out inappropriately,” added the team leader.

Fahmi explained that latex, which is often used, is a composition of substances that are difficult to decompose, such as rubber. Not only that, but latex can also cause skin allergies due to the high protein content in it. The chemicals that make it up are toxic. “The manufacture also uses ammonia, so the waste can damage the environment,” he added.

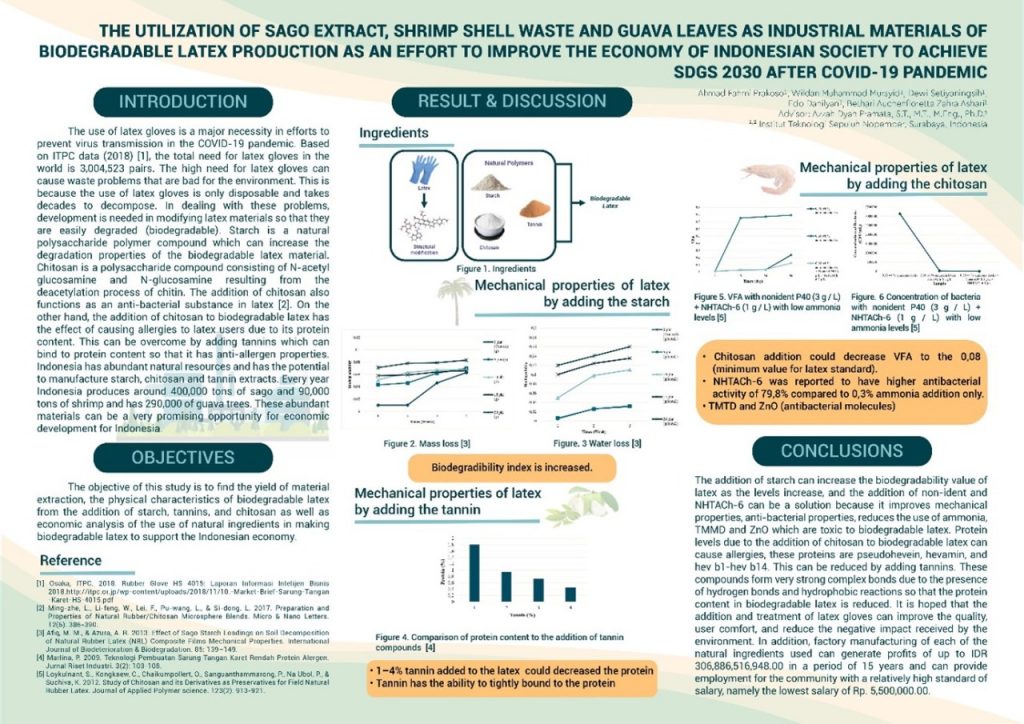

A poster of Green Engineer Team, the name of the team from Ahmad Fahmi Prakoso, presenting the innovation initiated

Based on this, Fahmi and other team members who are members of the Green Engineer Team initiated an innovation related to the use of environmentally friendly latex. Such latex has the same mechanical properties, but its constituents do not cause allergies to the skin. “So it provides comfort for users,” he said.

This Student of ITS Department of Material and Metallurgical Engineering said the natural ingredients used come from sago starch, shrimp skin waste, and guava leaves. The reason for using the material is because of its abundant stock and limited utilization. “We see all the ingredients have a chance and have advantages, but not put to good use,” said Fahmi.

Fahmi explained that they used sago starch because it is a biodegradable substance. Sago also has the highest levels of starch compared to other carbohydrate sources. Then, guava leaves contain tannins that can bind to allergy-causing proteins. “We used Shrimp skin waste because it has a chitosan substance that is antibacterial,” he continued.

This Student of the class of 2018 affirmed that the environmentally friendly latex initiated by his team has an advantage compared to other products. According to him, other environmentally friendly latex focuses on decomposition only but does not pay attention to the mechanical properties of materials, antibacterials, and allergic protein binding substances. “That’s what our latex advantages are,” he said.

Ahmad Fahmi Prakoso and other team members when presenting their innovations at the 2021 ASEAN Innovation Science and Entrepreneur Fair (AISEEF) online

From this idea, the paper of this team won the international competition. The team won a silver medal at the ASEAN Innovation Science and Entrepreneur Fair (AISEEF) 2021 in the Environmental Science category held last February.

Alumni of SMAN 1 Depok hopes that his innovation can develop to an industrial scale to improve Indonesia’s economy and step into the international scene. “I hope this innovation can inspire everyone to solve environmental problems in Indonesia,” he concluded. (pan/ITS PUBLIC RELATIONS)

Reporter: ion12

Related News

-

ITS Lecturer Introduces Madurese Culture to the International Stage

ITS Campus, ITS News — Continuing to show local wisdom to the world community, this time a lecturer from the Department

March 12, 2021 19:03 -

ITS Researchers Remind TKDN is Crucial for Economic Independence

ITS Campus, ITS News — The Domestic Component Level (TKDN) is the key to restoring the glory of the Indonesian

March 12, 2021 19:03 -

Strengthening Quality Education, ITS Professor Develops Adaptive Technology for Students

ITS Campus, ITS News — Differences in students’ abilities in understanding lessons are often a challenge for teachers in the classroom.

March 12, 2021 19:03 -

ITS Graduates Create Reverse Logistics Model for PET Plastic Waste Recycling

ITS Campus, ITS News — Doctoral graduate from the Department of Industrial and Systems Engineering, Sepuluh Nopember Institute of Technology (ITS) Dr. Yuniar

March 12, 2021 19:03