ITS Professor Brings Breakthrough in Nyamplung Oil Purification Method

Prof. Setiyo Gunawan ST Ph.D. in Professor Inauguration Scientific Oration, which was held online

ITS Campus, ITS News – The mangrove ecosystem, which continues to decline due to the massive conversion of land functions, raises its concerns regarding preserving the coast. Seeing this problem, the Professor (Gubes) of the Sepuluh Nopember Institute of Technology (ITS), Prof. Setiyo Gunawan ST Ph.D., who was inaugurated on Wednesday (31/3), was moved to develop alternative Batch-wise Solvent Extraction technology to utilize oil from nyamplung (mangrove) seeds. To support sustainability and maximize the benefits of mangroves.

Nyamplung, an associate mangrove plant, is planted in Indonesia as a barrier to tidal waves. Plus, each part of nyamplung has various benefits, such as nyamplung seed oil, which is helpful as fuel or as a medicine to relieve specific allergies.

The lecturer, who is usually called Gunawan, said, so far, there has been no research related to the refining of nyamplung oil. “Whereas (nyamplung oil) can be used as a high-value product for human needs, both food and non-food,” he said.

According to Gunawan, in refining nyamplung oil as a source of edible oil, it is necessary to pay attention to selecting the right method. Where the technology that is usually used in industry today is chemical refining and physical refining.

Professor Inauguration Scientific Oration in the Field of Food Material Technology by Prof. Setiyo Gunawan ST PhD

However, both methods have a process stage that is considered dangerous. “First, the method uses excess sodium hydroxide alkaline chemical compounds in the neutralization process so that it can pollute the environment,” explained the lecturer of the ITS Chemical Engineering Department.

Apart from that, he continued, the halalness of the contaminants resulting from removing most of the undissolved dye (bleaching) in the oil is doubtful. In most vegetable oil industries, this process said Gunawan uses activated carbon derived from animal bones because the price is low. “However, this will be a danger if animal bones such as pigs are used because they do not meet religious safety requirements for Muslims,” explained the Head of the ITS Center for Halal Studies (PKH).

Still, about the current refining process stages, there is a dangerous compound content of 3-Monochloropropane-1,2-diol (MCPD) Ester in the resulting cooking oil where the activation of these compounds’ formation occurs in the addition of acid in the degumming process.

Also, there is a deodorization process that requires high-temperature use in the process. “So we need a solution in the form of an efficient method to be free from these compounds,” explained the alumnus of the National Taiwan University of Science and Technology (NTUST).

Batch-wise Solvent Extraction Technology Breakthrough by Prof. Setiyo Gunawan ST Ph.D. in Nyamplung Oil Refining Process

Therefore, this Professor of Food Technology developed a renewal of cooking oil refining technology using the Batch-wise Solvent Extraction method. This method has been proven to be safer and more straightforward because it replaces the functions and stages of degumming, neutralization, and bleaching in a current way. Not only that, the burden of the deodorization process is lighter because it uses a lower temperature for its operation.

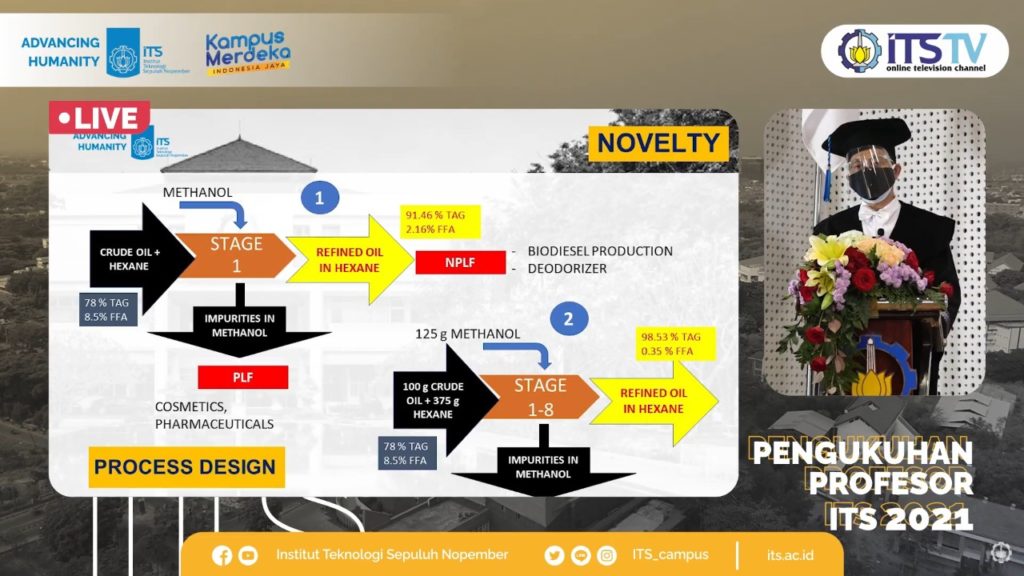

In this method, the polarity difference concept is used to refining cooking oil when nonpolar compounds dissolve in nonpolar solvents and vice versa. The triacylglycerol (TAG) content in cooking oil makes it soluble in hexane solvent and will collect in nonpolar liquid fraction (NPLF), which represents 74.1 percent of nyamplung crude oil. “Only then can it be used as raw material for biodiesel production or a deodorizer in the production of cooking oil,” said the officer of the Biochemical Technology Laboratory.

Meanwhile, according to Gunawan, free fatty acid (FFA) compounds and other impurities will dissolve in methanol solvent and gather in polar liquid fraction (PLF) to be used in the cosmetic, pharmaceutical industries. With the Batch-wise Solvent Extraction method, which increases the number of stages of the process, the refining of cooking oil can grow from 78 percent to 91.46 percent in stage one and 98.5 percent in stage eight.

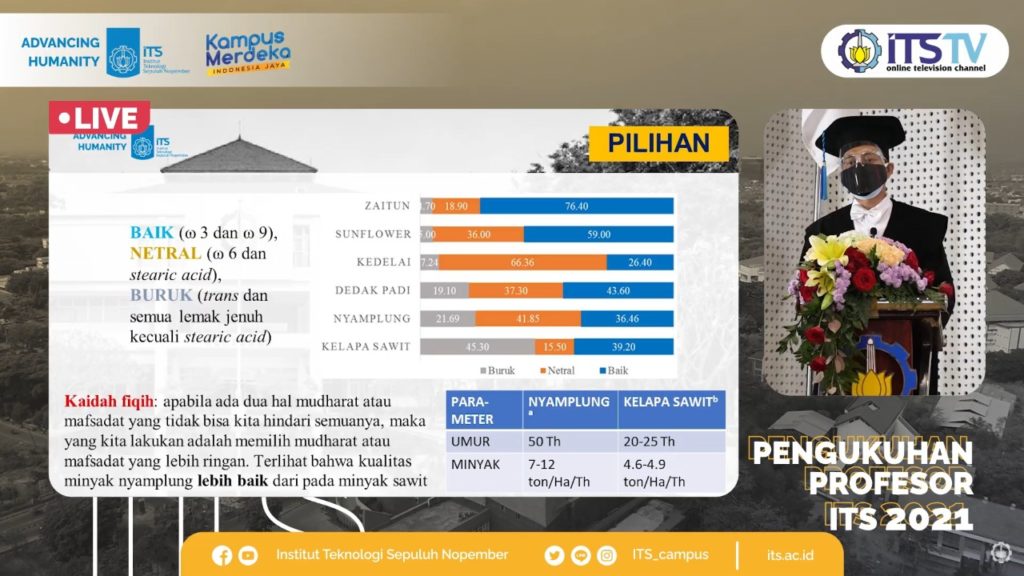

The explanation of the advantages of nyamplung oil over palm oil is based on its composition and economic aspects.

When compared with the quality of other vegetable oils such as palm oil, it is still seen that the quality of nyamplung oil is promising to be marketed because the quality of harmful fatty acids is more minor than palm oil. Following the fiqh rules, if there are two things that we cannot avoid all of them, then what we do is choose a lighter one. “Economically, the production of nyamplung oil is 7-12 tonnes per year, higher than palm oil which is only five tonnes per year,” said Gunawan.

Thus, considering its superiority, the idea of using nyamplung oil conveyed by the lecturer who was born in 1976 can also encourage a green economy which is suitable for supporting President Joko Widodo’s (Jokowi) ‘s program. This is because the nyamplung plant has high resistance to extreme conditions, such as solid winds, brackish water, and drought. Also, the preservation of the ecosystem can reduce the impact caused by the tsunami disaster.

Also, Gunawan stated that this idea could support the Halal Industrial Park program launched by President Jokowi because the production process does not involve acidic, alkaline, and unclean chemical compounds. “So that halal as a quality, safety and health requirement in the use and consumption of its products for consumers and industrial players can also be fulfilled,” he concluded hopefully. (ITS Public Relations)

Utilization of Nyamplung Oil as a Solution for Mangrove Ecosystem Conservation for Tsunami Disaster Mitigation

Reporter: Astri Nawwar Kusumaningtyas

Related News

-

ITS Lecturer Introduces Madurese Culture to the International Stage

ITS Campus, ITS News — Continuing to show local wisdom to the world community, this time a lecturer from the Department

March 31, 2021 17:03 -

ITS Researchers Remind TKDN is Crucial for Economic Independence

ITS Campus, ITS News — The Domestic Component Level (TKDN) is the key to restoring the glory of the Indonesian

March 31, 2021 17:03 -

Strengthening Quality Education, ITS Professor Develops Adaptive Technology for Students

ITS Campus, ITS News — Differences in students’ abilities in understanding lessons are often a challenge for teachers in the classroom.

March 31, 2021 17:03 -

ITS Graduates Create Reverse Logistics Model for PET Plastic Waste Recycling

ITS Campus, ITS News — Doctoral graduate from the Department of Industrial and Systems Engineering, Sepuluh Nopember Institute of Technology (ITS) Dr. Yuniar

March 31, 2021 17:03