ITS Students Initiate Solid Electrolyte Batteries from Bamboo Rope

(from left) ITS Neutrino Team consisting of M Fatahillah Aqsa Laksana Noah’s Ark, Andyan Rafi Setopratama, and Phahul Zhemas Zul Nehan

ITS Campus, ITS News – The need for batteries due to the development of electric cars, which the current government is intensifying, is increasing. However, unfortunately, electric car batteries, which are currently commercialized, are still considered environmentally unfriendly and expensive. Departing from these problems, the Neutrino Team from the Sepuluh Nopember Institute of Technology (ITS) initiated the solid electrolyte of electric car batteries extracted from a bamboo rope.

Reporting to CNBC, the need for electric car batteries could reach 198 GWh by 2050. However, commercialized electric car batteries still use liquid electrolytes that are corrosive, volatile, and explode due to a short circuit. “By changing to a solid electrolyte, this risk can be minimized due to its higher thermal stability,” explained Andyan Rafi Setopratama, Head of the Neutrino Team.

Not only that continued the student, who is familiarly called Rafi, but commercial electric car batteries will also become B3 waste (toxic, hazardous materials) if disposed of in the environment. This is because they still use synthetic materials such as polyethylene and polypropylene. These synthetic materials are also expensive, so the price of commercial electric car batteries is also high. “Even the price of a Tesla electric car battery is equivalent to the price of an Avanza car,” said this Physics Department student.

The team, consisting of two other students from the Physics Department class of 2019, namely Phahul Zhemas Zul Nehan and M Fatahillah Aqsa Laksana Bahtera Nuh, was inspired by a similar study conducted by Ndruru in 2019 using cocoa husks. In contrast to Ndruru, the solid electrolyte created by the Neutrino Team uses rope bamboo, which is often found in Indonesia.

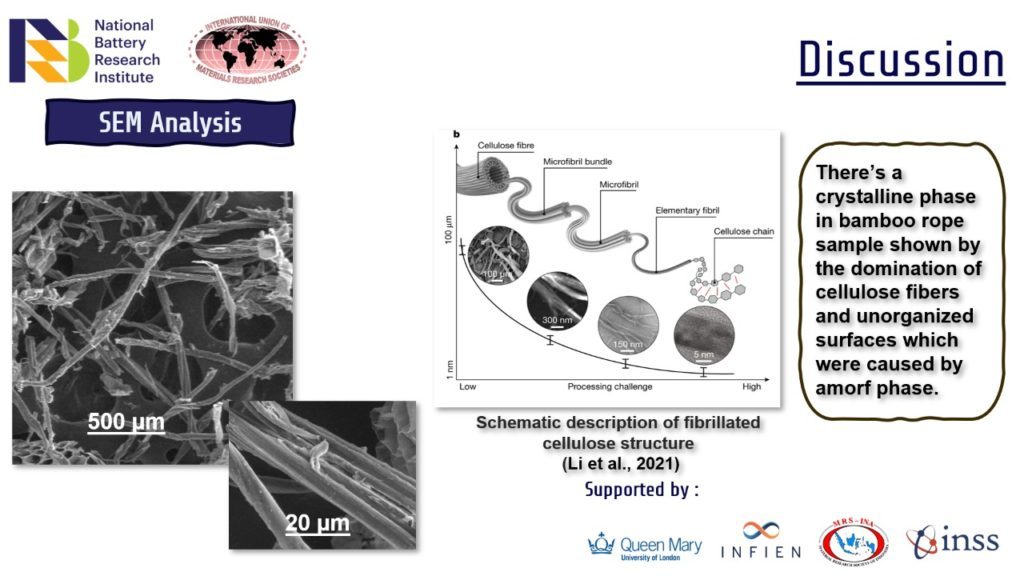

The structure of cellulose fibers found in rope bamboo

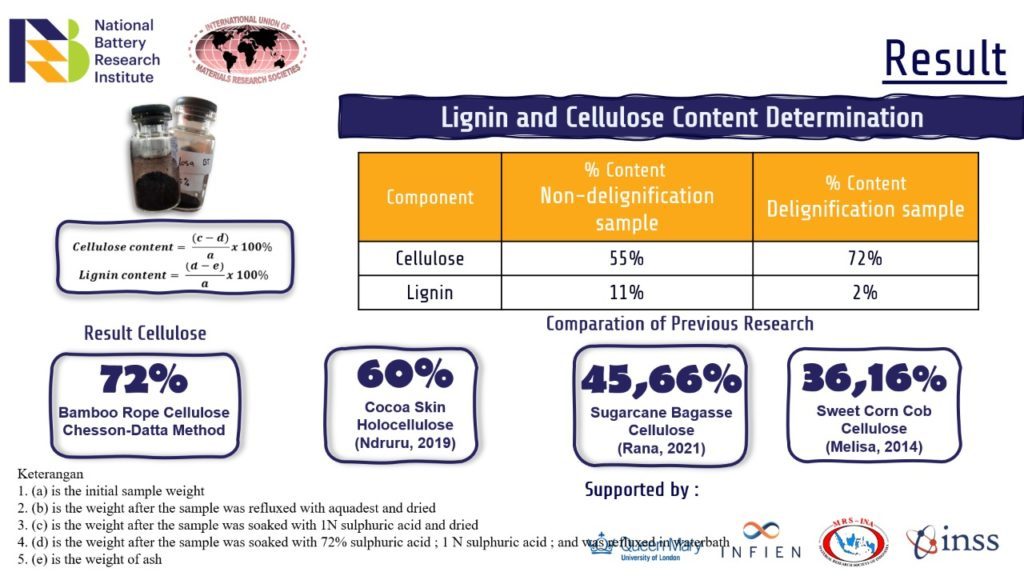

The manufacture of solid electrolytes is carried out in five stages. The first step is to determine the levels of cellulose and lignin contained in rope bamboo. Using the Chesson-Data method, it was found that rope bamboo contains 72 percent cellulose and 5 percent lignin. This cellulose content is the highest compared to similar studies using other natural ingredients such as cocoa husk, bagasse fiber, and sweet corn cobs.

Then proceed with the extraction of cellulose content using the Microwave-Assisted Extraction (MAE) method, which produces cellulose powder. Next is the synthesis of carboxymethyl cellulose or Carboxy Methyl Cellulose (CMC) with the addition of monochloroacetic acid (MCA) and isopropanol. The fourth stage is synthesizing ionic liquid, which is finally mixed with CMC powder to become a solid electrolyte biopolymer.

The cellulose content of rope bamboo is the highest level among other natural materials that have been studied

Unfortunately, according to Rafi, this research is still in the third stage due to limited time. Necessary materials in the study, such as lithium perchlorate salt, are also expensive and difficult to find in Indonesia, so they must be imported from abroad. “In the end, we did what was already there,” said the born student in 2001.

The research carried out for approximately four months has succeeded in bringing the Neutrino Team to third place in the 2021 Youth Idea Competition organized by the National Battery Research Institute. Not only that, but this research article is also in the process of being published in the journal International Symposium and Physic Application.

The student from Jember hopes that battery research will continue to develop so that he can create a small electric car battery with a large capacity and low cost. “Because the cost of batteries is cheap, electric cars can of course also be marketed at affordable prices,” he concluded optimistically. (ITS Public Relation)

Reporter: Dian Nizzah Fortuna

Related News

-

ITS Lecturer Introduces Madurese Culture to the International Stage

ITS Campus, ITS News — Continuing to show local wisdom to the world community, this time a lecturer from the Department

April 05, 2022 19:04 -

ITS Researchers Remind TKDN is Crucial for Economic Independence

ITS Campus, ITS News — The Domestic Component Level (TKDN) is the key to restoring the glory of the Indonesian

April 05, 2022 19:04 -

Strengthening Quality Education, ITS Professor Develops Adaptive Technology for Students

ITS Campus, ITS News — Differences in students’ abilities in understanding lessons are often a challenge for teachers in the classroom.

April 05, 2022 19:04 -

ITS Graduates Create Reverse Logistics Model for PET Plastic Waste Recycling

ITS Campus, ITS News — Doctoral graduate from the Department of Industrial and Systems Engineering, Sepuluh Nopember Institute of Technology (ITS) Dr. Yuniar

April 05, 2022 19:04