Helping Onion Farmers, ITS Student Community Service Program Designs Solar Powered Instore Drying

Display of instore drying buildings with smart solar panels equipped with temperature sensors and microcontroller assistance designed by the ITS KKN Abmas team

ITS Campus, ITS News – The potential for the shallot commodity could be threatened with a decrease in quality due to the current unfavorable weather. Helping to overcome this, the Sepuluh Nopember Institute of Technology (ITS) through Community Service (KKN Abmas) created an instore drying tool with the application of smart solar panels to maintain quality shallots.

Representing the ITS Community Community Service Team, Dr. Suyatno SSi MSi said that the cause of the decrease in the quality of shallots was due to unfavorable weather during the drying process, so that the shallots were half cooked. This was investigated due to weather that was too hot, as well as humidity during storage which resulted in onions becoming deflated, rotting, growing mushrooms, and growing shoots.

Limited tools and technology for post-harvest results also cause shallots to be sold directly without going through the storage process first. This causes farmers to not be able to sell shallots with quality quality according to the desired time. “That’s why we are trying to offer a solution for implementing storage with the help of solar panels as the main source of electricity,” he said.

Storage based on instore drying is considered capable of drying and storing post-harvest results, as well as maintaining the quality of shallots for a certain time in accordance with the Indonesian National Standard (SNI). Not only that, the advantage of this tool is that it can reduce the damage of shallots from 3.9 percent to 0.83 percent per one bunch with an average weight of 2-3 kilograms.

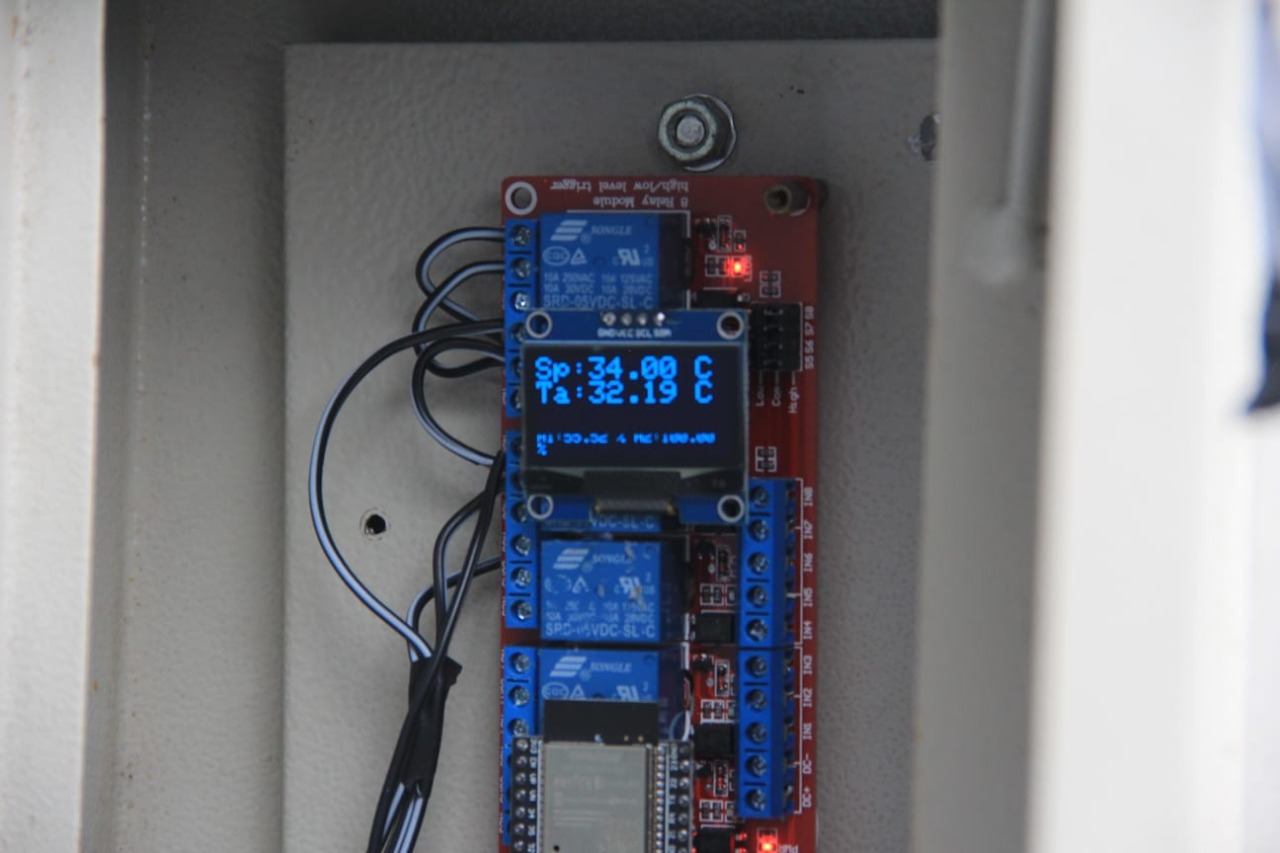

Sistem perancangan sensor suhu yang dikontrol menggunakan arduino dengan dikendalikan oleh mikrokontroler

Especially with the use of smart solar panels to run the system without the need for PLN electricity, which of course will reduce operational costs. This system also consists of a temperature sensor which is controlled using Arduino and will be controlled by a microcontroller so that it runs automatically making it easier for the fostered partners. “That way, the effective storage time, which usually only lasts four weeks, has increased to six months,” explained Suyatno.

Furthermore, according to Suyatno, the capacity of this designed instore drying will later be developed from 10 kilograms for a prototype into a tool that can accommodate shallots in quantities of up to 100 kilograms or even 1 ton. So, with land owned by related partners, it can accommodate the entire harvest of shallots with quality quality results.

Submission of a plaque as a sign of handing over the design of the instore drying prototype building to one of the shallot farmers, ITS Community Service Community Service partners in Kajang Hamlet, Nganjuk Regency

The ITS Community Service Abmas team with partners after visiting and completing the installation of the Instore Drying tool in Kajang Hamlet, Sukomoro District, Nganjuk Regency

The Abmas KKN which was held in the shallot producing village, Kajang Village, Nganjuk Regency was assisted by 18 students from the ITS Physics Department. This activity is targeted to be able to answer all the challenges of onion farmers. Starting from using the product to help maintain the quality of the quality shallot yields, to increasing the income of shallot farmers. It is hoped that this innovation can also support the government in improving the quality of shallots to be used as a quality export ingredient.

In the end, Suyatno also expressed his hope that the research being conducted would continue to be developed in order to help farmers become more prosperous. He hopes that students will care more about the agricultural environment, and contribute both during planting, tending, and harvesting. “We have a responsibility to farmers by helping solve their problems,” he concluded. (ITS Public Relation)

Reporter: Fauzan Fakhrizal Azmi

Related News

-

ITS Collaboration with BPBD East Java, Launching VR Disaster Simulation

ITS Campus, ITS News — Supporting anticipation of disasters and continuing to educate the public, Institut Teknologi Sepuluh Nopember

October 28, 2022 13:10 -

Supporting the Implementation of Innovative Ideas, ITS and IYSA Hold International Competition

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) has once again proven its commitment to supporting the

October 28, 2022 13:10 -

ITS Maintains Informative Qualification for Five Consecutive Years at KIP Awards

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) has once again successfully maintained its Informative Qualification predicate

October 28, 2022 13:10 -

ITS Strengthens Smart Eco-Campus through UI GreenMetric 2024

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) has once again demonstrated its commitment to environmental concern

October 28, 2022 13:10