ITS Lecturer Designs a Software as A Solution for Pump Complexity

The Mechanical Engineering Lecturer ITS, Nur Ikhwan, S.T., M.Eng., shows the software for pump sizing simulation that he designed

ITS Campus News – Institut Teknologi Sepuluh Nopember (ITS)y academician never stops producing various innovations for Public. One of them was conducted by The Mechanical Engineering Lecturer ITS, Nur Ikhwan, S.T., M.Eng. who succeeded in developing pump sizing simulation software.

The man who is familiarly called Ikhwan explained, the pump is one tool that is widely used in industries that involve liquids. To determine the right pump, it also requires the right calculation. “Precise calculations can be obtained with the help of software to simulate calculations before being applied to real conditions,” he explained.

According to Ihkwan, the existence of the software is also very important to support learning courses related to pump. However, to be able to use the software, so far users have to rent from abroad. “The costs incurred are quite large and can only be used on a number of devices,” he said.

Based on the issue, this lecturer who graduated from Memorial University of Newfoundland, Canada, and his team designed his own software pump selection simulation which can be used by students. The software can be accessed in myITS Classroom by students who need it. “Obviously with this software, there is no need to pay for foreign-made software to rent,” he said.

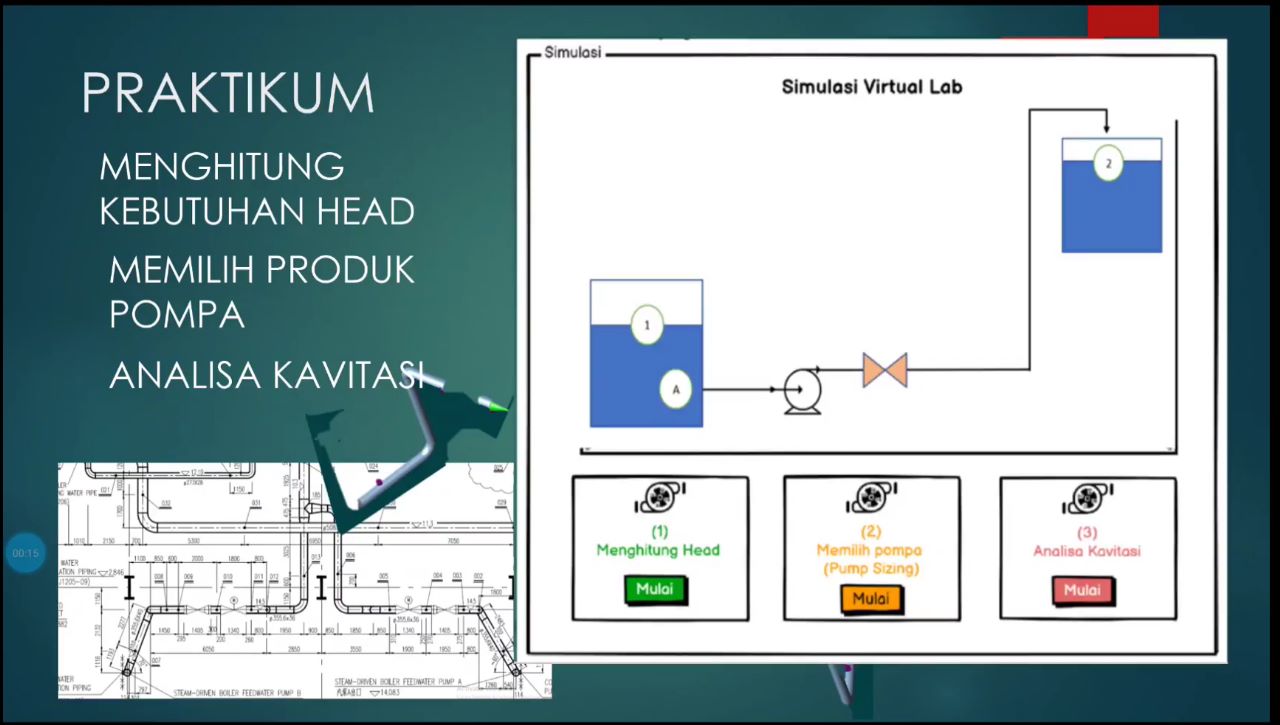

Pump selection simulation software scheme, designed by Nur Ikhwan, S.T., M.Eng., a lecturer from Department of Mechanical Engineering ITS

Furthermore, Ikhwan explained that the software for pump selection simulation is divided into three parts. The first simulation section aims to determine the pump head. “The pump head itself is the energy provided by the pump to the pumped liquid so that it can move from one place to another,” he explained.

In the second simulation, the pump head data in the first practicum together with the liquid flow rate data (discharge) are used to determine the right type of pump. “It doesn’t stop there, to perfect the pump design you get, it is necessary to ensure that the pump works optimally,” Ikhwan continued.

Therefore, the third simulation aims to ensure that the pump does not experience cavitation, which is the phenomenon of changing liquid into vapor as it flows. “This incident is indicated by the emergence of steam bubbles, vibration, and noise which can reduce performance and can damage the pump,” Ikhwan explained.

He admitted that the software developed under the Fluid Mechanics laboratory of Mechanical Engineering Department ITS has been used by students since 2021. “I hope that the software for pump selection simulation that we have designed can help students understand the study of pumping system analysis with easy access,” he concluded. (ITS PR)

Related News

-

ITS Develops Four‑Legged Dog Robot with Sensors and Navigation

ITS Campus, ITS News – Institut Teknologi Sepuluh Nopember (ITS) is further solidifying its role in robotic technology

December 25, 2022 09:12 -

ITS Mathematics Alumnus Creates EEG-Based Brain Research Technology

ITS Campus, ITS News — One of the graduates of the Institut Teknologi Sepuluh Nopember (ITS) has succeeded in

December 25, 2022 09:12 -

ITS Promotes FAST-D Scholarship, Unggul, and Global Excellence Scholarship

ITS Campus, ITS News – Institut Teknologi Sepuluh Nopember (ITS) always shows its commitment in supporting students to develop their best

December 25, 2022 09:12 -

Supporting the Implementation of SPMB 2025, ITS Develops the SENOPATI Platform

ITS Campus, ITS News – Showing its contribution in the field of education, Institut Teknologi Sepuluh Nopember (ITS) has redeveloped a platform

December 25, 2022 09:12