ITS Abmas Innovates CNC Milling to Increase Production of UKM Manufacture

ITS Abmas Team and UD ACC workers, a UKM manufacture located in Bulak District, Surabaya

ITS Campus News – In the production process, the majority of Small and Medium Enterprises (UKM) in the manufacturing sector still use conventional methods. In order to increase the effectiveness and efficiency of this production, the Community Service (Abmas) Team of Institut Teknologi Sepuluh Nopember (ITS) innovated a tool called Computer Numerical Control (CNC) Milling.

ITS Abmas team member, Mashuri SSi MT, said that one of the UKM manufacture in Surabaya is UD ACC. This UKM itself focuses on the fabrication and manufacture of workpieces that are commonly used to make machines. “The machines produced by UD ACC have reached the national market, both inside and outside Java,” he said.

Unfortunately, continued Mashuri, UD ACC often experiences problems such as production capacity that is not in line with market demand. This occurs due to the use of production equipment manually. “This non-optimal production process causes UD ACC to often reject orders from prospective buyers,” said Mashuri.

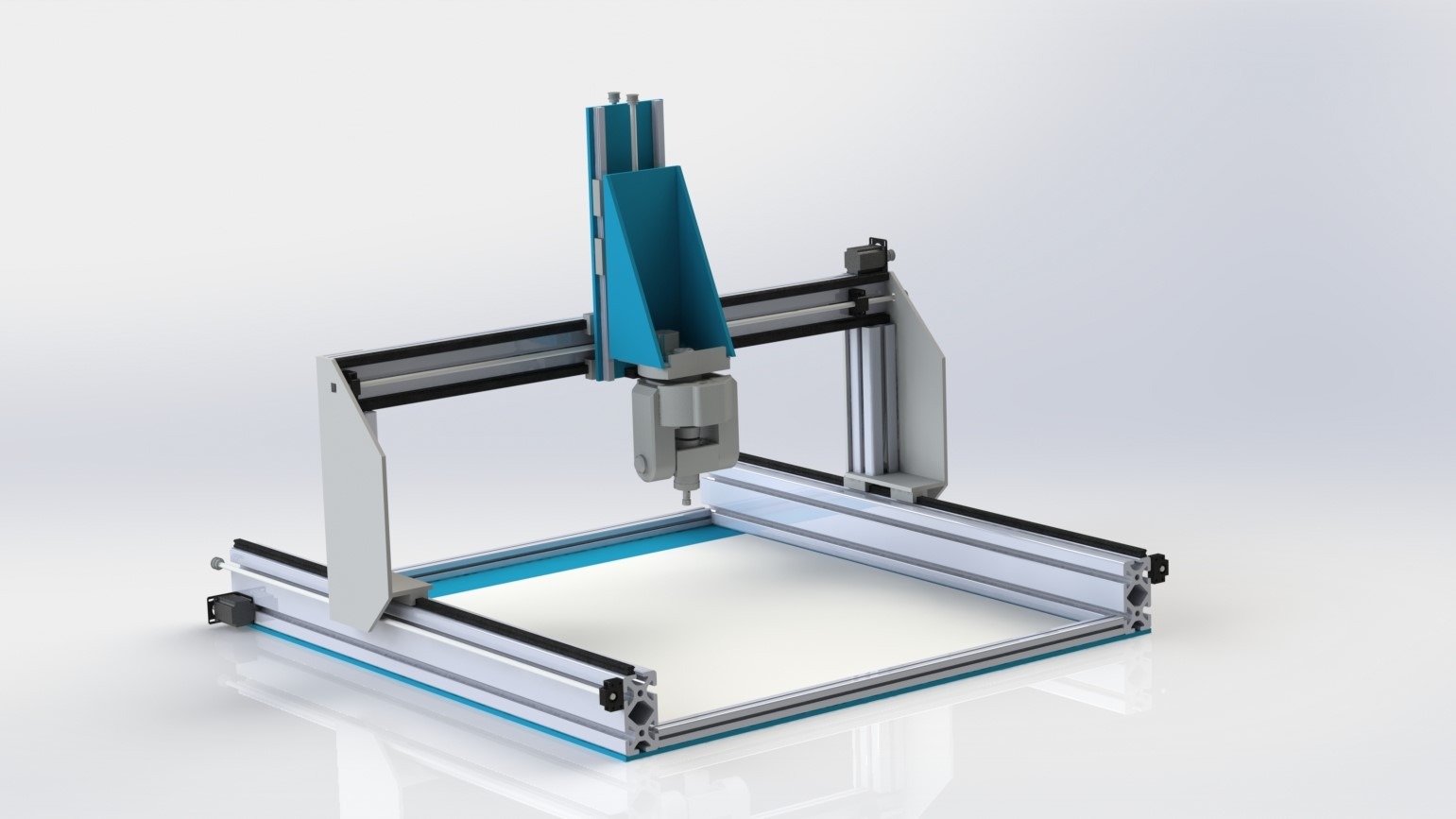

Based on these problems, ITS Abmas team finally designed a CNC Milling, a machine that can work automatically and is able to improve the production process without needing to add manpower. The Abmas activity itself begins with direct observation to partners. “Furthermore, tool design, manufacturing processes, as well as training and assistance are conducted on the use of CNC Milling machines,” he explained.

The CNC Milling prototype designed by Mashuri SSi MT and ITS Abmas team to help increasing the production of UKM manufacture

According to Mashuri, the CNC Milling has the same basic function as a manual milling machine. However, manual milling machines require human power to continuously operate them. In addition, the quality of the workpiece produced also depends on the work of the machine operator. “In contrast, a CNC machine is able to maintain the stability of the quality of the workpiece produced because the operation comes from the machine,” he added.

The lecturer from Industrial Mechanical Engineering Department added that the CNC Milling works by reading the CNC program or better known as the G-Code. This code has previously been created by programmers through the CNC programming software. Furthermore, the G-Code will be sent and executed by the processor to drive the device in the machine to produce a product based on the program.

With this working principle, the risk of human error can be minimized and production speed can be increased. “We hope that this tool will be realized soon, so that production capacity and the market reached by UKM will increase,” concluded Mashuri hopefully. (ITS PR)

Related News

-

Faithful in Times of Joy and Sorrow, Married Couple Graduate with Doctorates Together at ITS

ITS Campus, ITS News — As though guided by one heart and one soul, Dr Hanugra Aulia Sidharta ST

December 26, 2022 11:12 -

ITS Wins 2024 Project Implementation Award for Commitment to Gender Implementation

ITS Campus, ITS News —Not only technology-oriented, Institut Teknologi Sepuluh Nopember (ITS) also show its commitment to support gender

December 26, 2022 11:12 -

ITS Professor Researched the Role of Human Integration in Sustainable Architecture

ITS Campus, ITS News –The developing era has an impact on many aspects of life, including in the field

December 26, 2022 11:12 -

ITS Sends Off Group for Joint Homecoming to 64 Destination Areas

ITS Campus, ITS News — Approaching Eid al-Fitr, the Sepuluh Nopember Institute of Technology (ITS) is once again facilitating academics who want

December 26, 2022 11:12