ITS Innovates Processing of Tofu Industrial Liquid Waste into Synthetic Leather

The ITS student team demonstrated the tofu industrial wastewater treatment process to the public

ITS Campus, ITS News – Improper processing of tofu industrial waste can cause many environmental problems. Departing from this, the academic community Institut Teknologi Sepuluh Nopember (ITS) initiated an innovation to deal with the problem of tofu industrial wastewater into something more useful, such as synthetic leather.

As a first step, this innovation was applied in Sambiroto Village, Mojokerto Regency, to answer the area’s problems regarding industrial tofu waste. According to team leader Indah Tri Cahyani, this innovation also empowers the surrounding community.

Supervised by Ervin Nurhayati ST MT PhD, Indah and the team innovated a system so that people could process the tofu industrial wastewater themselves. Indah explained that initially, the community would ask the factory owner for the liquid waste from the tofu industry according to the required dose.

After obtaining the liquid waste from the tofu industry, the community will process the waste. The processing is carried out by boiling the tofu industrial liquid waste with the addition of certain chemicals. “The chemicals used include sugar, vinegar, food grade urea fertilizer mixed with Acetobacter xylinum bacteria,” said the Department of Environmental Engineering student.

The enthusiasm of the people of Sambiroto Village, Mojokerto, during the tofu industry wastewater treatment training activity initiated by a team of ITS students

Furthermore, Indah also explained that this innovation had also been arranged in such a way as to make it easier for the community. The convenience can be seen from the details of the dosage of chemicals used. Not only that, with the help of local youth organizations, Indah and the team also conducted community training to clarify waste treatment flow.

The initial product from the liquid waste boiling process is nata de soya, a food made from tofu industrial liquid waste. To become synthetic leather, nata de soya must be processed again by removing the water content. “The product produced after this process is synthetic leather, commonly called soya leather,” added Indah.

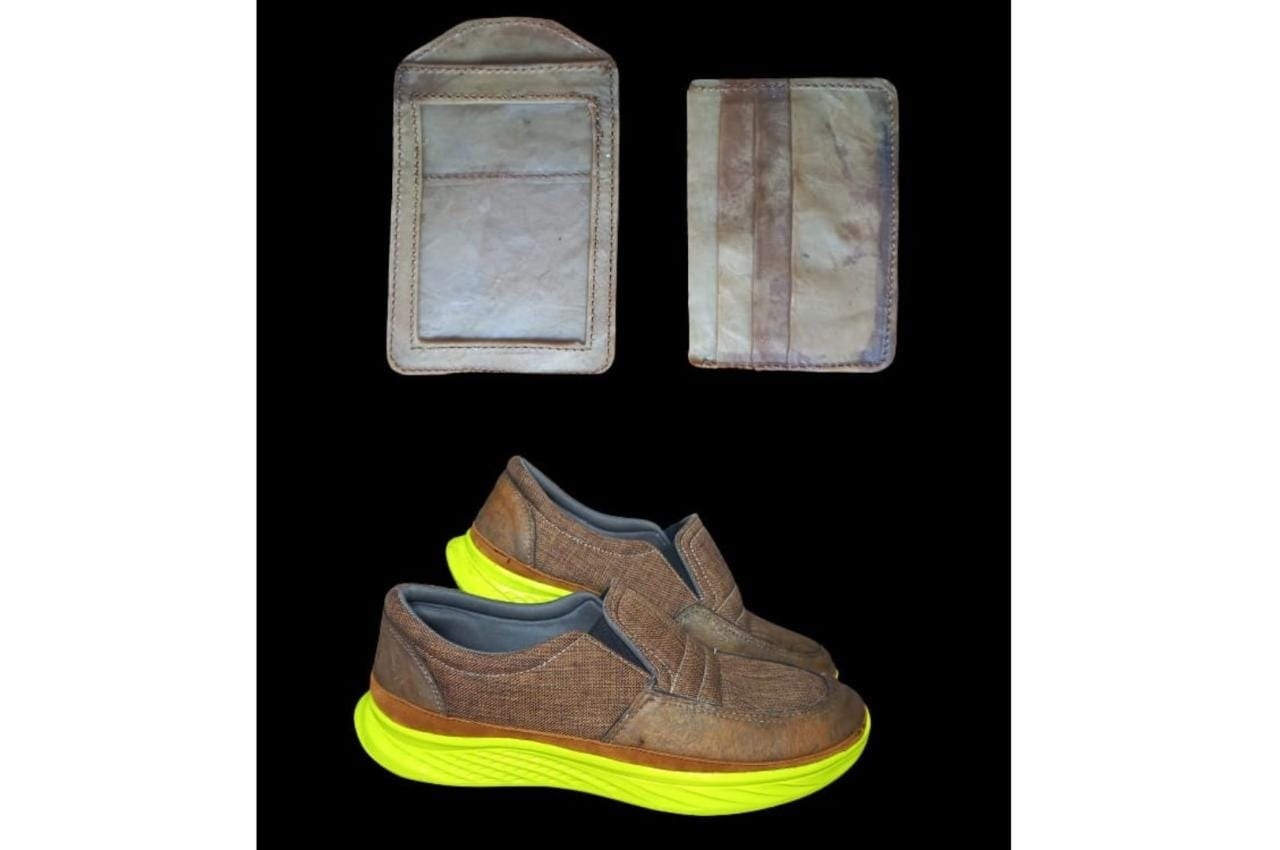

One of the displays of the final product innovation of industrial wastewater treatment is the idea of the ITS student team.

Indah said that her work with the team did not stop at producing these synthetic leather products. After making a raw product in the form of artificial leather, training will be carried out for synthetic leather artisans so they can process the raw material into materials with selling value, such as wallets and bags.

The team, which also includes Wijaya Sakti Muhammad Sampurna from the Department of System and Industrial Engineering, I Putu Bagus Adhi Pradana from the Department of Informatics Engineering, along with two students from the Department of Chemistry, namely Sinta Eka Septa Sari and Ardi Lukman Hakim, still want to continue to develop their innovations. After this continued Indah, community empowerment will continue to optimize synthetic leather products further.

The ITS team, when conducting socialization about the innovation of tofu industrial wastewater treatment to the people of Sambiroto Village, Mojokerto Regency

In addition to providing training, Indah and her team optimise synthetic leather products by establishing a cooperative. This cooperative was established so that the economic cycle would be more precise, which is essential because it is one of the efforts to improve the welfare of society.

This innovation also brought the ITS team to win the second-place title at the 35th National Student Scientific Week (Pimnas) at the University of Muhammadiyah Malang some time ago. “Hopefully, this innovation can continue to develop and answer people’s complaints about tofu industrial waste,” he concluded. (ITS Public Relations)

Reporter: Mohammad Febryan Khammam

Related News

-

Facilitating Creativity of Students, ITS Information Systems Department Presents CCWS

ITS Department of Information Systems students conduct a discussion in one of the available spaces in the ITS Digital

December 30, 2022 19:12 -

ITS Explores Electrification Cooperation with PT Vale Indonesia

ITS Campus, ITS News — Following up on the Memorandum of Understanding (MoU) with PT Vale Indonesia, Institut Teknologi

December 30, 2022 19:12 -

ITS Reaches Top 7 BRIN Collaborators with 309 Scientific Publications

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS) continues demonstrating its commitment to strengthening collaboration in research

December 30, 2022 19:12 -

The Only One from Indonesia, ITS Student Becomes Erasmus+ Scholarship Awardee

ITS Campus, ITS News — Civitas academica of Institut Teknologi Sepuluh Nopember (ITS) has once again contributed to making

December 30, 2022 19:12