Prevent Corrosion, ITS Students Initiate Utilization of Composite Materials

(from left) ITS Neutrino Team consisting of Intan Yulia Putri Perindasari, Phahul Zhemas Zul Nehan, and Andyan Rafi Setopratama

ITS Campus, ITS News – As a maritime country, Indonesia has wide seascapes with high levels of environmental humidity which can lead to high corrosion processes in ships. In order to slow down the corrosion process, students from Insititut Teknologi Sepuluh Nopember (ITS) researched and innovated the use of iron sand and rice husk ash waste for composite nanomaterials to be coatings on ship hulls.

Phalul Zhemas Zul Nehan, a student who is a member of the ITS Neutrino Team explained, corrosion on ship hulls is often caused by direct contact with seawater which has high conductivity resulting in oxidation events. It is analyzed that this can lead to swelling of the problem in terms of costs and the age of repairing ships.

With this main problem, Phalul and his two teammates, namely Intan Yulia Putri Perindasari and Andyan Rafi Setopratama, took the initiative to project innovation through the ship coating method, namely biomaterials. In the process, the materials used are iron sand and rice husk ash waste which are popular for making silica nanoparticles. It was designed on the grounds of low toxicity, high coercivity and biocompatible than other nano-sized materials.

The innovation of using iron sand and rice husk ash waste for magnetic and silica composite nanomaterials was initiated by a team of ITS students

Basically, continued Phalul, previous studies have shown that silica material is commonly found in nature and also in the form of rice husk ash waste. With the use of rice husk ash waste, it is considered to have great potential to make anti-corrosion coatings on carbon steel plates in ship hulls. “Thus, it is possible to withstand the diffusion of water vapor, oxygen ions to the metal surface,” he explained.

The use of this waste also has a positive impact with an efficiency of 81 percent to inhibit the corrosion rate. With this high efficiency, rice husk will have hydrophobic properties that are anti-wet, look always clean, so that it can reduce the friction of sea water with the surface of the hull. “This is an accurate solution to reduce ship coating production costs,” he said.

Based on the innovation of magnetic and silica composite materials, it is proposed that the work go through the review stage of several characterization test results from relevant previous studies. Furthermore, the test results show that the particle distribution will be right into the coating matrix, because it is able to create a barrier effect and reduce corrosive transport paths through the thickness of the coating.

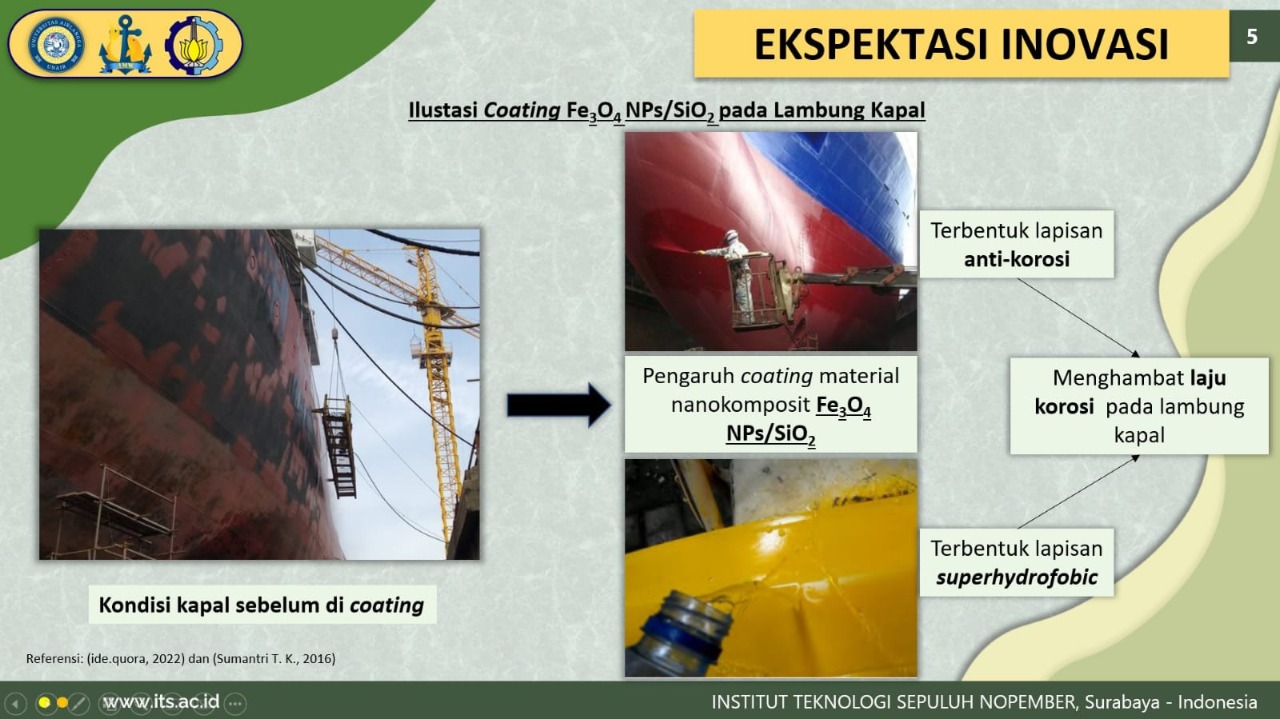

Projected expectations of innovation from the results of research on magnetic and silica composite coatings on ship hull steel conducted by the ITS Neutrino team

With other results in the form of mechanical and corrosion protection performance of the coating film which has a large impact based on the percentage of nanofiller used. The projection of this research has shown the homogeneous distribution of nanoparticles in order to determine the chemical and corrosion protective characteristics. “Later on, it will show the effectiveness of composite materials for each trial,” explained the student under the guidance of Retno Asih MSi PhD.

Finally, Phalul hopes that his team’s innovative ideas can continue to be a sustainable solution so that they can overcome the corrosion problem in the hull steel which is supported by the hydrophobic nature of the material. “It is also suggested that there is an increase in the quality of research observations to find out further the potential for development,” he concluded.

Thanks to this innovative creativity, the team consisting of three students from the Department of Physics succeeded in winning 1st place and Best Presentation in the Airlangga Maritime Week 2022 scientific writing competition, recently. With the research title Utilization of Iron Sand and Rice Husk Ash Waste for Fe3O4/SiO2 Composite Nanomaterials as Anti-Corrosion Coatings on Ship Hulls. (ITS Public Relations)

Reporter: Fauzan Fakhrizal Azmi

Related News

-

ITS Wins 2024 Project Implementation Award for Commitment to Gender Implementation

ITS Campus, ITS News —Not only technology-oriented, Institut Teknologi Sepuluh Nopember (ITS) also show its commitment to support gender

December 31, 2022 00:12 -

ITS Professor Researched the Role of Human Integration in Sustainable Architecture

ITS Campus, ITS News –The developing era has an impact on many aspects of life, including in the field

December 31, 2022 00:12 -

ITS Sends Off Group for Joint Homecoming to 64 Destination Areas

ITS Campus, ITS News — Approaching Eid al-Fitr, the Sepuluh Nopember Institute of Technology (ITS) is once again facilitating academics who want

December 31, 2022 00:12 -

ITS Expert: IHSG Decline Has Significant Impact on Indonesian Economy

ITS Campus, ITS News — The decline in the Composite Stock Price Index (IHSG) by five percent on March 18,

December 31, 2022 00:12