ITS Professor Develops Green Industry-Based Polymer Processing

Prof. Dr. Ir Sumarno MEng when delivering his inaugural scientific oration as the 157th Professor of ITS regarding polymer processing based on environmentally friendly technology

ITS Campus, ITS News – Professor of the Institut Teknologi Sepuluh Nopember (ITS) who has just been inaugurated as the 157th Professor of ITS, Prof. Dr. Ir Sumarno MEng, initiated an innovation in polymer processing based on the Green Industry. This innovation brings benefits to the world by reducing environmental problems due to conventional polymerization processes.

Through his inaugural scientific oration, this professor from the ITS Chemical Engineering Department said that the innovation he initiated was the use of the High-Intensity Energy Process method. This method utilizes intensively released physical energy so that it can reduce a polymer compound. “This method is more environmentally friendly when compared to conventional methods which involve gases that destroy the ozone layer such as freon,” said the ITS Chemical Engineering graduate.

Furthermore, the man who was born in Lumajang, on 8 June 1964 said that High Shear Mixing (HSM), sonication, supercritical fluids, and hydrothermal are examples of High Intensity Energy Process methods. HSM itself is a method that uses high rotational speed in the process. Meanwhile, sonication and hydrothermal methods are closely related to ultrasonic waves.

Human skeleton bone model made from a mixture of synthetic and natural polyols

In the innovations given, the Head of the ITS Chemical Engineering Materials Technology laboratory made four scientific contributions to the world. The four contributions include sonication, HSM and hydrothermal for biopolymer processing, supercritical fluids for microcellular plastic foam, polyurethane from a mixture of synthetic and natural polyols, and hydroxyapatite for denture base.

Sumarno revealed that scientific contributions in the form of sonication, HSM, and hydrothermal in biopolymer processing raised the issue of processing hazardous chemicals in sengon wood and cassava ray. In processing sengon wood itself, a combination of sonication and hydrothermal methods is used which plays a role in producing Microcrystalline Cellulose (MCC), which is the main focus of sengon wood processing. Meanwhile, the HSM method is used to produce RS-3 which is also the main focus of cassava processing.

The father of three children also continued that the scientific contribution in the form of supercritical fluid in the manufacture of microcellular plastic foam produces a plastic-based foam. Supercritical fluid technology in the plastic foaming process minimizes the use of excess organic solvents. “Therefore, the negative impact on the environment can be significantly reduced,” emphasized the recipient of the Satyalancana Karya Satya X award.

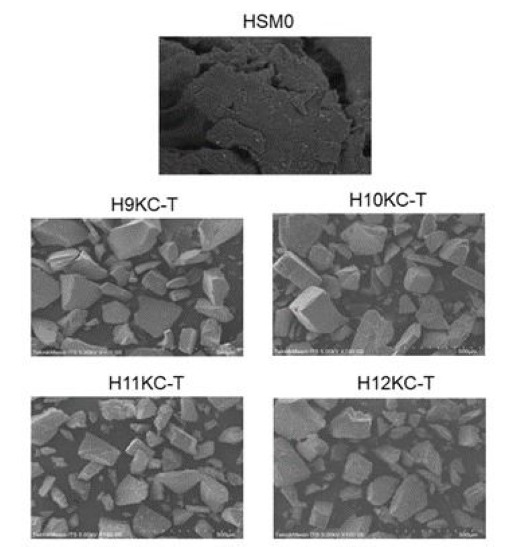

Scanning Electron Microscope (SEM) images of low-calorie starch products from cassava starch retrogradation assisted by the High Shear Mixing (HSM) method and continued centrifugation

For the scientific contribution of Polyurethane material from a mixture of synthetic polyols and nature itself, the husband of Nurlaili Qodaria takes advantage of the rigid nature of Polyurethane material as a material for modeling human skeletons. This scientific contribution is very useful to support the orthopedic learning model.

Finally, the scientific contribution made is Hydroxyapatite (HAp) as a denture base. In this case, the HAp method is used which acts as a filler in the denture base composite. This scientific contribution departs from dental and oral problems in humans that often occur.

In addition to scientific contributions to the world, this innovation also results in scientific renewal. The resulting innovations are High-Intensity Energy for processing polymers, supercritical technology in polymer processing, and natural polymers for functional polymer composites. (ITS Public Relation)

Reporter: Ahmad Farhan Alghifari

Related News

-

ITS Develops Four‑Legged Dog Robot with Sensors and Navigation

ITS Campus, ITS News – Institut Teknologi Sepuluh Nopember (ITS) is further solidifying its role in robotic technology

May 22, 2023 18:05 -

ITS Mathematics Alumnus Creates EEG-Based Brain Research Technology

ITS Campus, ITS News — One of the graduates of the Institut Teknologi Sepuluh Nopember (ITS) has succeeded in

May 22, 2023 18:05 -

ITS Promotes FAST-D Scholarship, Unggul, and Global Excellence Scholarship

ITS Campus, ITS News – Institut Teknologi Sepuluh Nopember (ITS) always shows its commitment in supporting students to develop their best

May 22, 2023 18:05 -

Supporting the Implementation of SPMB 2025, ITS Develops the SENOPATI Platform

ITS Campus, ITS News – Showing its contribution in the field of education, Institut Teknologi Sepuluh Nopember (ITS) has redeveloped a platform

May 22, 2023 18:05