ITS Governor Initiated Environmentally Friendly and Sustainable Nickel Ore Processing

Prof. Sungging Pintowantoro ST MT Ph.D. Eng when presenting his scientific oration regarding sustainable nickel ore processing at the inauguration event

ITS Campus, ITS News – The increase in carbon dioxide (CO2) emissions due to the use of nickel as an industrial raw material threatens the sustainability of processing this metal mineral ore in the future. Responding to this problem, the 169th Professor of the Institut Teknologi Sepuluh Nopember (ITS), Prof. Sungging Pintowantoro ST MT PhD Eng, presented a solution through a direct nickel reduction process and utilization of nickel solid waste.

Through his scientific oration entitled Mastering the Processing of Nickel Ore and Other Metal Minerals to Support Sustainable Domestic Metal Production, Sungging expressed his concerns regarding the current processing of nickel ore. “Nickel is a mineral metal whose use is very promising, but the emissions produced can damage the environment,” said Sungging.

In his research, he proposed the direct reduction process as an alternative effort to producing nickel ore. In more detail, this process was chosen to reduce energy use in ore processing which will later impact the emissions that will be produced. “This method produces a lower operating temperature, so the energy used is more efficient,” explained the professor from the ITS Department of Materials and Metallurgical Engineering (DTMM).

Not only is it more efficient, but according to Sungging, the direct reduction product has a higher nickel content due to the use of additives. Based on his research, Sungging found that ammonia gas is an additive with quite high effectiveness in maximizing nickel content. “Ammonia gas is also cheaper than the hydrogen gas that is usually used,” said the father of Hanania Kirei Pintowantoro and Yukio Timoti Pintowantoro.

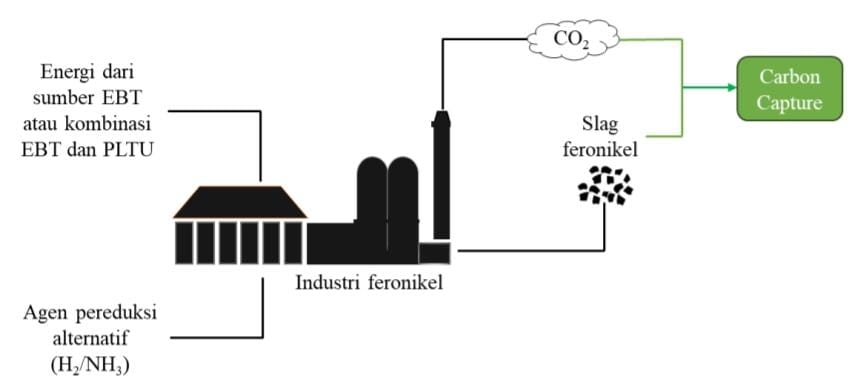

The scheme was initiated by Prof. Sungging Pintowantoro ST MT Ph.D. Eng to create an environmentally friendly and sustainable nickel industry in the future

In its application, ammonia gas will produce nitrogen gas and water after the production process. These two environmentally friendly components can later be reprocessed to produce new ammonia gas. “It is very suitable for sustainable use,” explained the professor who is also the Head of the ITS DTMM Mineral and Material Processing Laboratory.

Discussing the nickel ore production process in more depth, Sungging explained that the production of metallic minerals produces relatively large amounts of solid waste, including nickel. Therefore, a brilliant idea to use nickel solid waste to capture CO2 is another smart innovation that Sungging offers through his research.

Furthermore, Sungging explained that nickel solid waste contains several non-carbonate compounds such as magnesium, calcium, and iron. These three compounds will react with CO2 and form highly stable carbonate compounds. “In the future, carbon dioxide (CO2) gas will remain bound in minerals for a long time,” explained this alumnus of the doctoral program from Tohoku University, Japan.

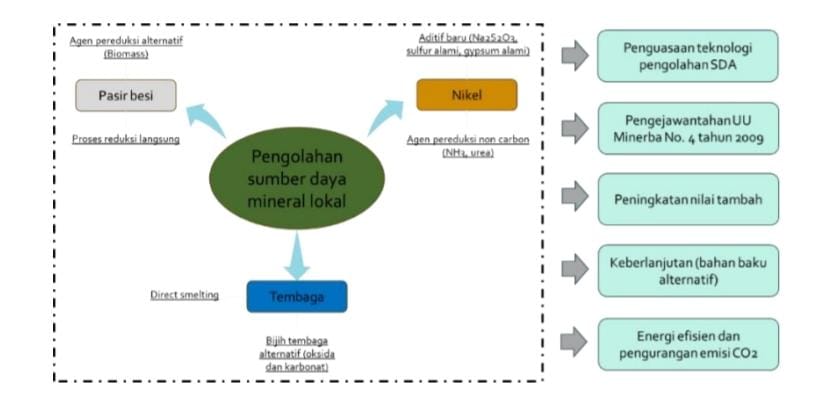

Scheme of the benefits of environmentally friendly and sustainable mineral ore processing proposed in the research of Prof Sungging Pintowantoro ST MT Ph.D. Eng from ITS

By combining the direct reduction process and the utilization of nickel solid waste, energy-efficient and environmentally friendly nickel ore processing is no longer just a dream. Sungging has proven this step to be theoretically feasible to implement and develop. However, this innovation will not be realized on a mass scale if it is not accompanied by the use of good mineral processing technology.

The man, who is now 55 years old, underlined that educational steps to achieve technological mastery must be carried out immediately. This is motivated by non-renewable metal mineral resources. “The government must immediately move to create policies that can help people’s understanding of technology,” he stressed.

This member of the ITS Academic Senate emphasized that industry and academics play a very important role in helping to master technology. He suggested that the government needs to increase the competence of academics as well as their involvement in the mineral ore processing process. “This involvement leads to practical academic skills that can be passed on to the nation’s successors,” he said.

Ketua Dewan Profesor ITS Prof Dr Ir Imam Robandi MT (kiri) saat memberikan sertifikat pengukuhan Prof Sungging Pintowantoro ST MT PhD Eng sebagai profesor ke-169

In this way, various steps to improve other mineral technology, such as building mineral research centers and strengthening regulations for improving research facility facilities and infrastructure, can follow. “I hope that this innovation can provide benefits to both the nation and existing natural resources in a sustainable manner,” concluded Sungging, confirming his hopes. (ITS Public Relations)

Reporter: Hibar Buana Puspa

Related News

-

ITS Develops Four‑Legged Dog Robot with Sensors and Navigation

ITS Campus, ITS News – Institut Teknologi Sepuluh Nopember (ITS) is further solidifying its role in robotic technology

November 09, 2023 15:11 -

ITS Mathematics Alumnus Creates EEG-Based Brain Research Technology

ITS Campus, ITS News — One of the graduates of the Institut Teknologi Sepuluh Nopember (ITS) has succeeded in

November 09, 2023 15:11 -

ITS Promotes FAST-D Scholarship, Unggul, and Global Excellence Scholarship

ITS Campus, ITS News – Institut Teknologi Sepuluh Nopember (ITS) always shows its commitment in supporting students to develop their best

November 09, 2023 15:11 -

Supporting the Implementation of SPMB 2025, ITS Develops the SENOPATI Platform

ITS Campus, ITS News – Showing its contribution in the field of education, Institut Teknologi Sepuluh Nopember (ITS) has redeveloped a platform

November 09, 2023 15:11