Glass Bowl Molds Manufacturing Using CNC Milling Machine

In early June 2021, PT UDEO, which is a startup company from ITS, received an order to make 20 molds for glass bowls from PT MIKRONIKA MAKMUR Sidoarjo. This company produces a variety of die, mold and factory equipments to serve the needs of maintenance and replacement of factory machines.

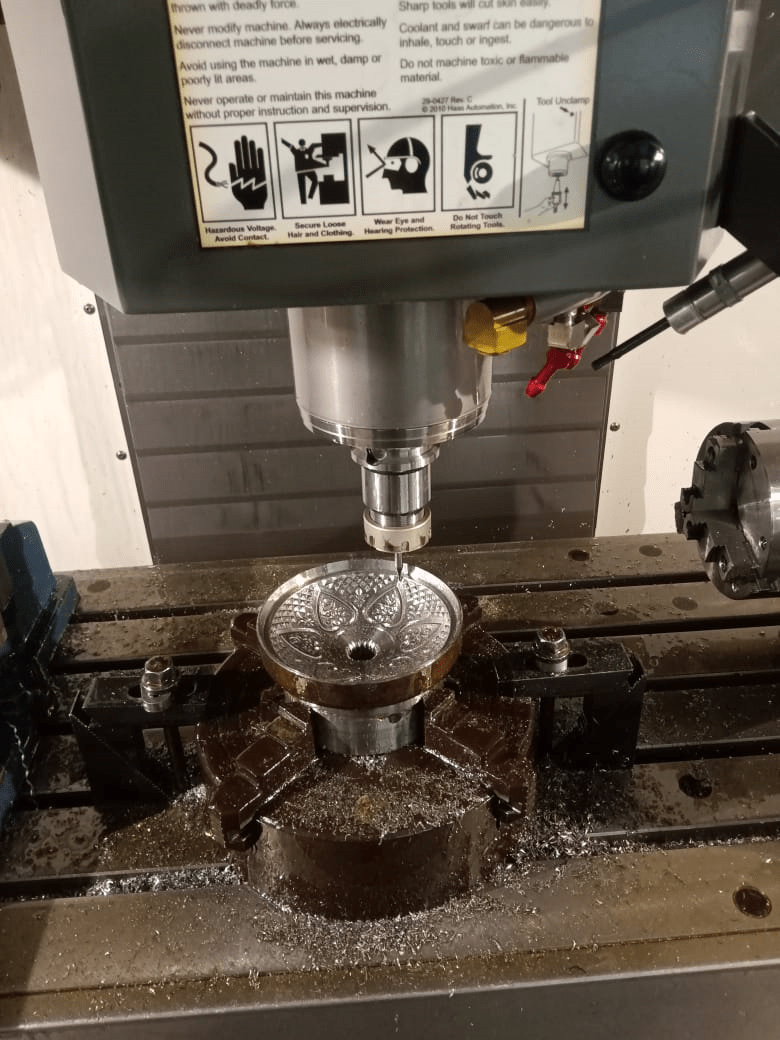

This order is currently being done using a HAAS VF3 CNC Milling machine in the Molina Building belonging to PUI SKO ITS, which also has 4 axes milling capability, with the maximum workpiece size of 1 m x 0,5 m. For the order, the material of choice is Stavax Steel, which is the normal material used for manufacturing molds. One mold job takes up to 8 hours to complete. This relatively long time to work for a product was due to the hardness of Stavax material which can potentially damage the toolset if not done with the correct methods.

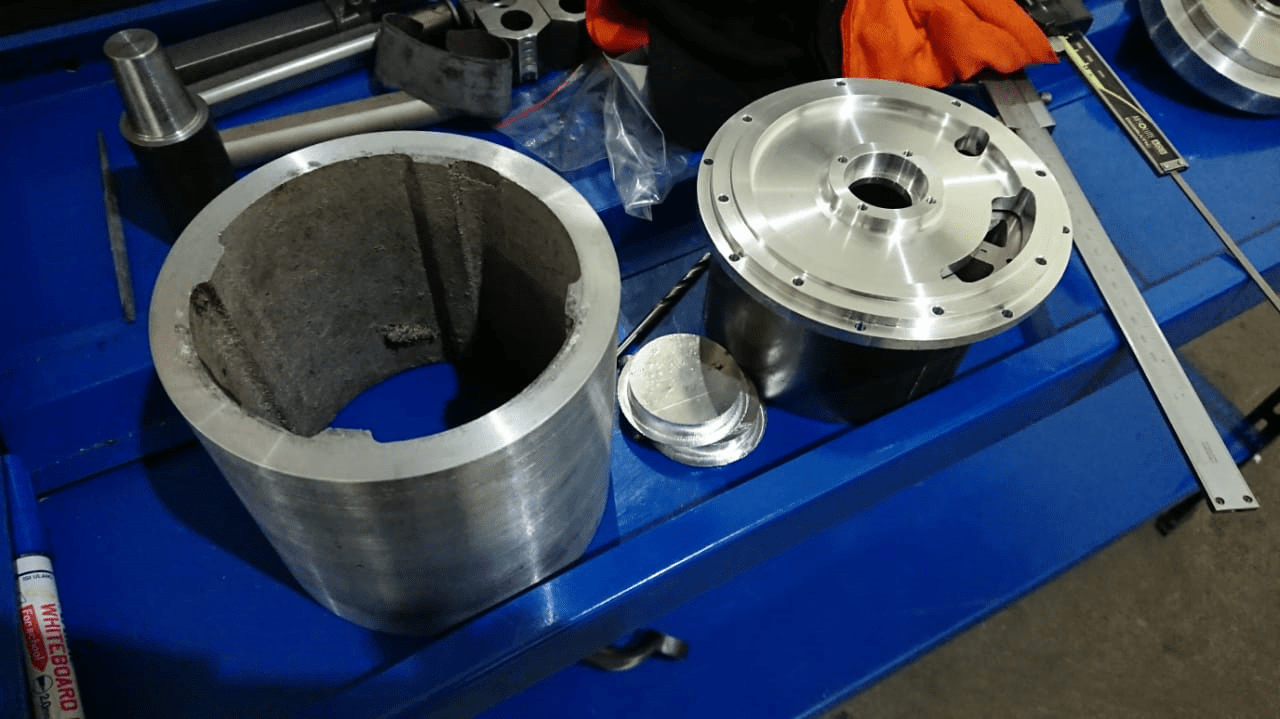

In addition to a CNC Milling machine, PUI SKO ITS also has a HAAS ST10 CNC Lathe Machine, which can turn workpieces up to a maximum diameter of 6 inches, and a maximum length of 30 cm. With these two CNC machines, the products that can be worked on become much more diverse. As an example, in addition to the mold work, the CNC machines at PUI SKO ITS have also been used to work on other products, such as custom spare parts for electric motors from PT BRAJA ELEKTRIK MOTOR, like Rotor, Stator, Casing, Fin, and other custom sized accessories that are not commonly sold in the market.

Related News

-

Ministry of Education and Science Supports Downstreaming of ITS Research Towards Real Economic Impact

Deputy Minister of Higher Education, Science, and Technology (Diktisaintek) of the Republic of Indonesia Prof. Stella Christie PhD when

May 30, 2021 08:05 -

Through STP, ITS Strives to Strengthen Downstream Research Products

ITS Chancellor Prof Ir Bambang Pramujati ST MScEng PhD giving a speech at the STP National Seminar at the

May 30, 2021 08:05 -

EVITS Becomes an Environmentally Friendly Transportation Solution at the East Java Transportation Agency

Director of PT ITS Tekno Sains Dr Ir I Ketut Gunarta MT (left) when symbolically handing over the EVITS

May 30, 2021 08:05 -

BENGCARE, a Platform to Connect Workshops and Communities Digitally

ITS Campus, ITS News — The mismatch in price and quality in choosing a workshop is certainly a dilemma

May 30, 2021 08:05