Bachelor Degree (S1)

OVERVIEW

The Bachelor Degree of Materials and Metallurgical Engineering Study Program , Faculty of Industrial Technology and Systems Engineering (IND-SYS), Institut Teknologi Sepuluh Nopember has the scientific field, expertise and profession of Materials Science and Engineering . The Materials and Metallurgical Engineering Study Program, has scientific fields, expertise and professions in Material Engineering and Metallurgical Engineering. Various types of materials are used in various fields of human life needs. Various materials are used as technical components to meet the various needs of human life. Materials science and technology and metallurgy are required to produce high quality materials. This forms the Field of Science and Expertise in Materials Engineering and Metallurgy. In general, Materials and Metallurgical Engineering studies the properties (properties) of metal (metal) materials, ceramics, polymers and composites and their engineering technology. Material engineering and metallurgical properties consist of mechanical properties, physical properties, chemical properties, thermal properties, electrical properties and others. Materials engineering technology deals with the structure of materials and their manufacturing processes such as casting, welding, heat treatment and others. The field of science and expertise in Material Engineering and Metallurgy is built on three foundations of knowledge of structure, properties and material processing as a Body of Knowledge

PROFILE OF GRADUATE

Individual who is able to solve problems in profession of materials -metallurgical engineering and other with good moral personality and leadership as continuous self improvement

AUTONOMOUS PROFILE OF MATERIALS AND METALLURGICAL ENGINEERING DEPARTMENT

- Individual who are able to solve problems in managing and utilizing local, national and global resources based on the principles of basic science and materials-metallurgical engineering

- Individual who has good moral personality and leadership, able to communicate and solving in task in organization considering profession ethics and other ethic

- Individual who is able to do continuous self improvement

LEARNING OUTCOME

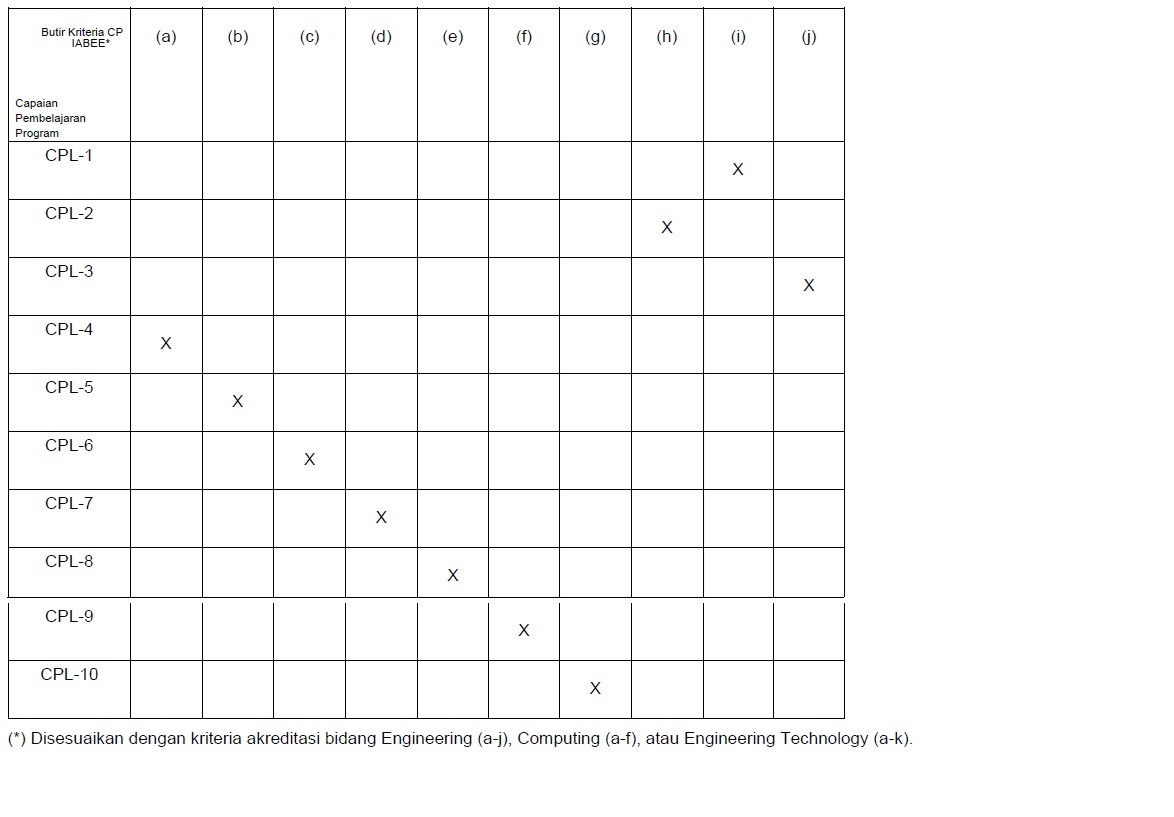

- CPL – 1 Able to demonstrate attitudes and characters that reflect: piety to God Almighty, ethics and integrity, virtuous character, sensitive and concerned about social and environmental issues, respecting cultural differences and pluralism, upholding high law enforcement, prioritizing the interests of the nation and the wider community , through creativity and innovation, excellence, strong leadership, synergy, and other potentials to achieve maximum results

- CPL – 2 Able to carry out a study that utilizes science and technology to the field of industrial systems engineering and able to make appropriate decisions from the results of their own work or group work in the form of final project reports or other forms of learning activities whose output is equivalent to the final project through logical thinking, critical thinking, systematic, and innovative

- CPL – 3 Able to manage self-learning and develop oneself as a personal lifelong learner to compete at national and international levels, in order to make a real contribution to solve problems by implementing information and communication technology based on the principles of sustainability and technology-based entrepreneurship

- CPL – 4 Able to solve materials engineering and metallurgical problems using science, technology, and mathematics

- CPL – 5 Able to design components, systems, and processes for materials and metallurgical engineering based on engineering, economy, energy, environment, and sustainability

- CPL – 6 Able to formulate decisions based on data analysis, information, experiments, and or practical experience

- CPL – 7 Able to identify, analyze and formulate alternative solutions for materials engineering and metallurgy

- CPL – 8 Able to apply modern tools for engineering design and analysis

- CPL – 9 Able to communicate effectively, both orally and writing

- CPL – 10 Able to plan, complete and evaluate tasks within existing constraints as needed

Suitability CPL Prodi dan CPL IABEE

- Education Implementation Survey click here

- Document of Survey Results for Alumni and Graduate Users, click here

- Tracer Study Data: Click Tracer Study Document here

FIELD OF GRADUATES

In the Undergraduate Program in the department of material engineering and metallurgy, there are 4 areas of expertise, namely:

- Extractive Metallurgy

- Manufacturing Metallurgy

- Corrosion and Failure

- Innovative Materials

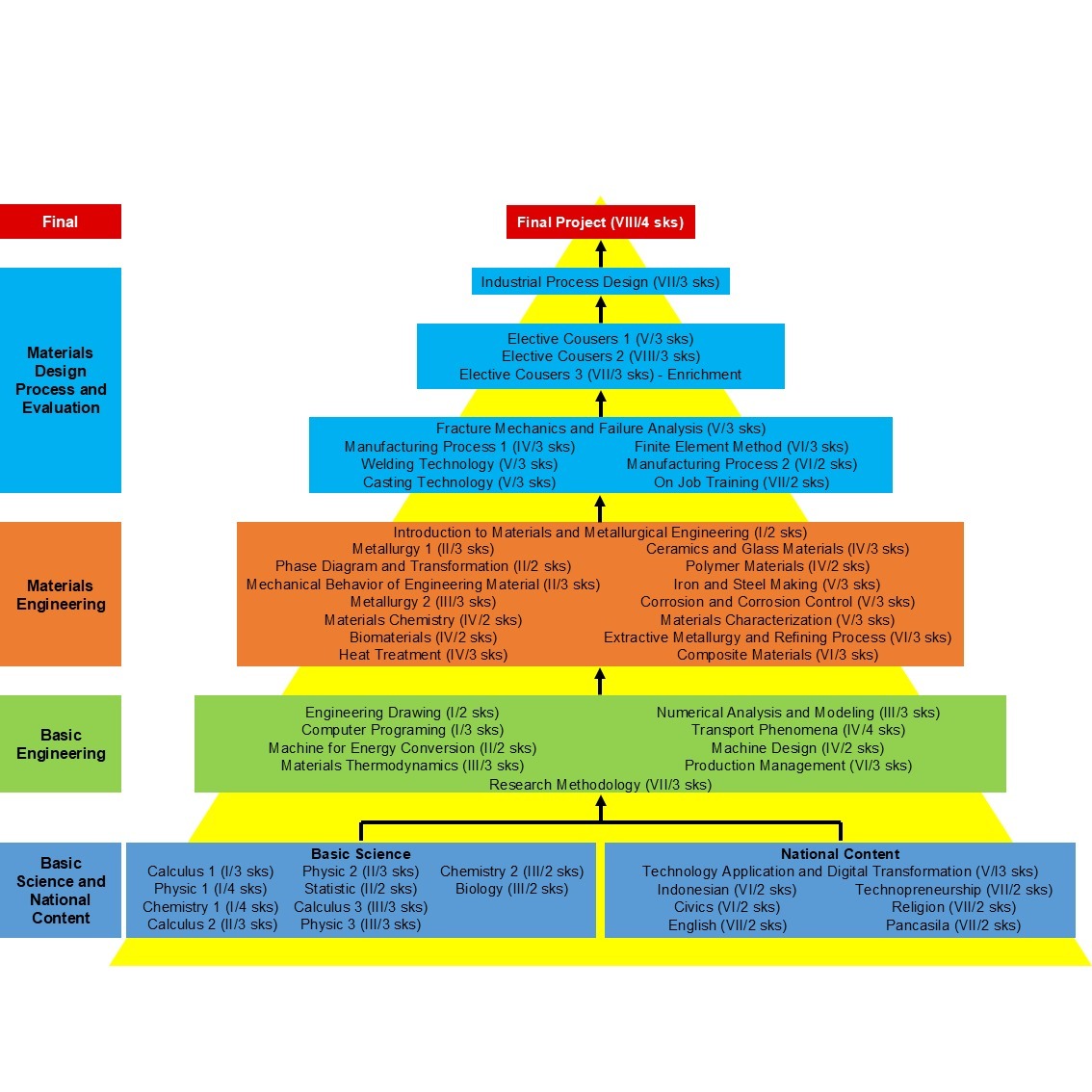

CURRICULUM STRUCTURE

CURRICULUM 2023-2028

CURRICULUM 2023-2028

| Matakuliah Semester 1 | SKS | Matakuliah Semester 2 | SKS | |

| Calculus 1 | 3 | Calculus 2 | 3 | |

| Mechanics Physics | 4 | Physics of Electricity and Magnetism | 3 | |

| Chemistry 1 | 4 | Statistics | 2 | |

| Introduction of Materials and Metallurgical Engineering | 2 | Metallurgical 1 | 3 | |

| Engineering and Machinery Drawings | 2 | Phase and Transformation Diagrams | 2 | |

| Computer Programming | 3 | Mechanical Behavior of Materials | 3 | |

| Jumlah SKS | 18 | Energy Conversion Machine | 2 | |

| Jumlah SKS | 18 |

Keterangan :

Semester 1 Semester 2

MK Mechanics Physics+ Lab Experiment MK Metalurgi 1 + Lab Experiment

MK Chemistry 1 + Lab Experiment

MK Engineering and Machinery Drawings +Big Task

| Matakuliah Semester 3 | SKS | Matakuliah Semester 4 | SKS | |

| Calculus 3 | 3 | Materials Chemistry | 2 | |

| Physics 3 | 3 | Transport Phenomena | 4 | |

| Chemistry 2 | 2 | Machine Elements | 2 | |

| Biology | 2 | Biomaterial | 2 | |

| Metallurgical 2 | 3 | Heat Treatment | 3 | |

| Materials Thermodynamics | 3 | Manufacturing Process 1 | 3 | |

| Numerical Analysis and Modeling | 3 | Ceramic and Glass Materials | 3 | |

| Polymer Materials | 2 | |||

| Jumlah SKS | 18 | Jumlah SKS | 21 |

Information :

Semester 3 Semester 4

MK Metalurgi 2 + Lab Experiment MK Materials Chemistry + Lab Experiment

- MK Heat Treatment + Lab Experiment

- MK Manufacturing Process 1 + Big Task

- MK Polymer Materials + Big Task

| Matakuliah Semester 5 | SKS | Matakuliah Semester 6 | SKS | |

| Iron and Steel Manufacturing Process | 3 | Technology Applications and Digital Transformation | 3 | |

| Welding Technology | 3 | Indonesian | 2 | |

| Corrosion and control | 3 | Citizenship | 2 | |

| Materials Characterization | 3 | Metallurgical Extraction and Refining Processes | 3 | |

| Fault Mechanics and Failure Analysis | 3 | Finite Element Method | 3 | |

| Casting Technology | 3 | Manufacturing Process 2 | 2 | |

| Choise 1 | 3 | Composite Materials | 3 | |

| Production Management | 3 | |||

| Jumlah SKS | 21 | Jumlah SKS | 21 |

Information :

Semester 5 Semester 6

MK Corrosion and control + Lab Experiment MK Metallurgical Extraction and Refining Processes + Lab Experiment

MK Materials Characterization + Big Task MK Manufacturing Process 2 + Big Task

MK Welding Technology + Big Task MK Composite Materials * Enrichment

MK Casting Technology + Big Task

| Matakuliah Semester 7 | SKS | Matakuliah Semester 8 | SKS | |

| English | 2 | Final Project | 4 | |

| Technology Based Entrepeneurship | 2 | Choises 3 | 3 | |

| Religion | 2 | Jumlah SKS | 7 | |

| Pancasila | 2 | |||

| Industrial Process Design | 3 | |||

| Research Methodology | 3 | |||

| Practical Work | 2 | |||

| Choises 2 Enrichment | 3 | |||

| Jumlah SKS | 19 |

Information :

Semester 7

MK Industrial Process Design + Big Task

LIST OF ELECTIVE COURSES

| No.

No. |

Kode MK

Course Code |

Nama Mata Kuliah (MK)

Course Name |

Sks

Credit |

| 1 | TL234540 | Non Destructive and Risk Based Inspection | 3 |

| 2 | TL234541 | High Temperature Corrosion | 3 |

| 3 | TL234542 | Electronics Materials | 3 |

| 4 | TL234543 | Materials Conversion and Energy Storage | 3 |

| 5 | TL234544 | Magnetic Materials | 3 |

| 6 | TL234545 | Polymer Technology | 3 |

| 7 | TL234546 | Wood Composite | 3 |

| 8 | TL234547 | Deformation and Forming Processes | 3 |

| 9 | TL234548 | Occupational Health and Safety | 3 |

| 10 | TL234849 | Advanced Materials Strength | 3 |

| 11 | TL234850 | Computational Fluid Dynamics | 3 |

| 12 | TL234851 | Composite Mechanics | 3 |

| 13 | TL234852 | Coating Technology | 3 |

| 14 | TL234853 | Recycling Technology | 3 |

| 15 | TL234854 | Materials For Maritime | 3 |

| 16 | TL234855 | Minerals Processing | 3 |

| 17 | TL234856 | Apprenticeship 1 | 3 |

| 18 | TL234857 | Apprenticeship 2 | 3 |

| 19 | TL234858 | Special topics: Engineering Economics, Optical Materials, Refractory Materials, Metallurgy Manufacturing, Powder Metallurgy, Superalloys, Quality control and reliability, Operational Research, Electronics and Instrumentation, Electrochemistry, Engineering Mathematics, Engineering Mechanics | 3 |

+P = Prakticum

+P = Laboratory practical

+TB = Big Task

+A = Assignment

*= Service Enrichment Course

*= Enrichment Course Service

COURSE SCHEDULE EVEN SEMESTER 2024-2025

For course schedule, click here

LIST DOCUMENT OF CURRICULUM

Download Curriculum Book 2014-2019 clik here

Download Assessment Method Plan 2018-2023 clik here

Download Curriculum Book 2018-2023 clik here

Download Curriculum Book 2023-2028 clik here

Download Semester Learning Plan Book 2018-2023 clik here

Download Curriculum Development book 2018-2023 click here

Download Syllabus Curriculum Development 2018-2023 clik here

Download RPS Curriculum 2018-2023 clik here

Download Quality Assurance Guide clik here

Download Transfer Credit for International Exchange Program click here

Download Procedure for Assessment, Evaluation and Follow Up of Learning Outcomes here

Download letter of additional learning outcomes in the judicial process here

Download Syllabus Curriculum 2018-2023 (SN DIKTI Version) here

Download Calender Academic 2023-2024 here